How To Select The Right Material For Cone Crusher Liners?

Which is the best material for cone crusher liners?

Standard Manganese Steel

The standard material for cone crusher liners is manganese steel, which is also called austenitic manganese steel or modified austenitic manganese steel. There are…

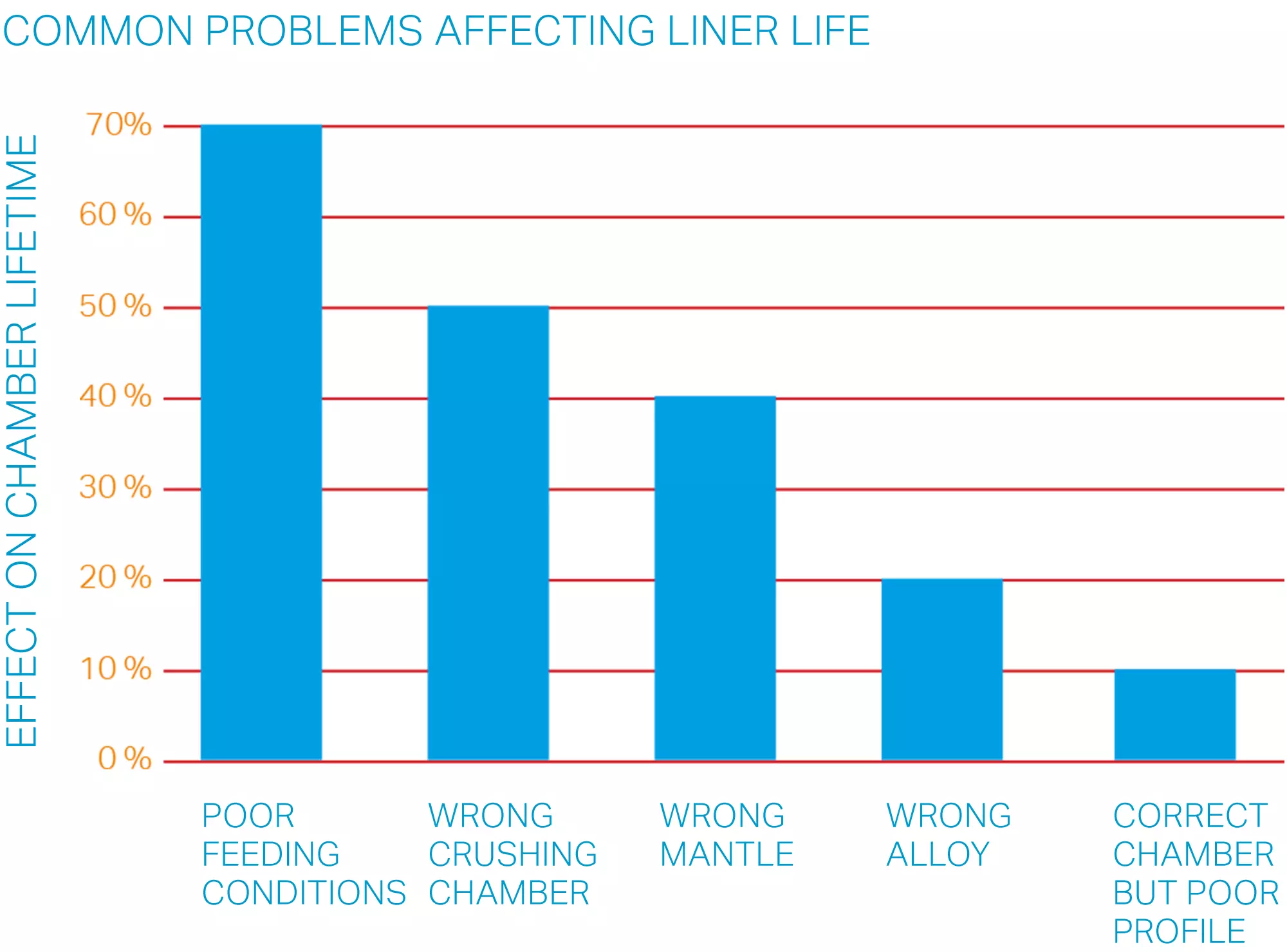

How To Prolong Cone Crusher Liners Span Life?

Extending the life of cone crusher liners

Whilst wear replacement is a necessary feature of any crushing operation, there are steps you can take to extend the service life of crusher wear parts.

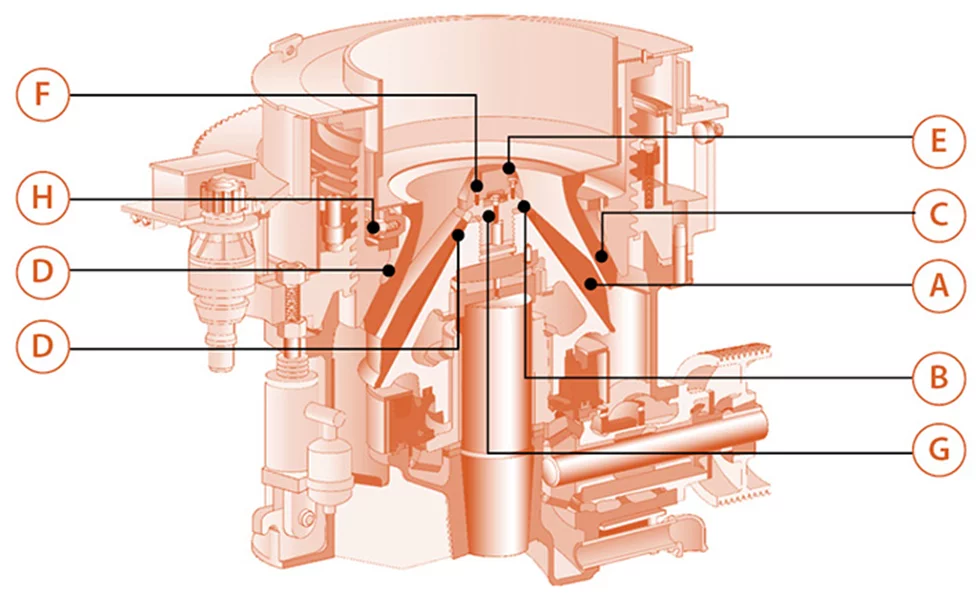

Always ensure the wear parts are fastened…

When & How To Change Cone Crusher Liners?

When to change cone crusher liners?

Liners that exceed their intended operating life will cause mechanical problems with the crusher. A liner that is pushed too long will flex and crack, and the flexing of a thin or cracked mantle will cause…

When to rotate crusher jaw plates?

The ideal situation would be when even wear occurs throughout the jaw plate area, using all the manganese teeth, eliminating the need to execute the “turn”, or change production.

This is impossible, however, because there are areas where…

When & How To Change Crusher Jaw Plates?

When to change crusher jaw plates?

There are two kinds of situations that need to change the crusher jaw plates:

The jaw crusher liners need to change before they are worn through, in order to avoid damage to the crusher components. Different…