Shredder Hammer By Hunan JY Casting

Shredders are widely used in metal scrap recycling. The Shredder device includes hammers joined to a massive rotor. Hammers are responsible for grinding, therefore, play a key role in the shredder.

Hunan JY Casting is a shredder hammers manufacturer in China. As replacement wear parts specialists, we have developed different advanced alloys and manufacturing techniques that really pay off in demanding applications such as scrap metal and solid waste shredding. Based on different working conditions, we carry a wide variety of wear hammers and styles for shredding scrap metal, steel, aluminum, wood, and rock.

- Manganese steel hammers

- TIC inserts hammers

- Ceramic inserts hammers

- Alloy steel hammers

Made to order to fit most auto and scrap metal shredders, hammer mills, and horizontal metal grinders, Hunan JY Castings shredder hammers reduce wear and tear to help you achieve better tons out than competing castings.

All Hunan JY Casting shredder hammers are cast in an ISO 9001 foundry from virgin materials and strict attention to detail. The result is a long-wearing, durable wear hammer that delivers more tons between grate changes and less casting-related downtime.

Alloy Shredder Hammers

Alloy Shredder Hammer

The hammers used in shredder lines represent a key factor in plant efficiency. Because the high manganese steel hammer is not very good in wear resistance when crushing scrap metal. In order to improve the service life of the hammer, our company invented a low carbon alloy hammer. This alloy hammer has high surface hardness and good ductility, which can greatly improve the service life of the hammer.

- Material: Alloy steel (30CrNiMo)

- Hardness: Gradient hardness. Hammer handles hardness around 48 HRC; Hammer head around 58 HRC.

- Working life: Around 1.5-2 times than manganese hammer

- Price: Around 1.5 times than manganese hammer

- Suitable material: Scrap metal

Manganese Shredder Hammers

Manganese Shredder Hammers

Manganese steel hammers basically have been around since the shredder was invented. Manganese is still the hammer of choice for the vast majority of shredders around the world. It is usually the lowest cost per processed ton performer and the most forgiving with baled and heavy scrap. If your product mix has a good percentage of heavier scrap to shred, you will be able to work harden the hammers for excellent wear. For best results, manganese hammers should have a minimum 1/2% Molybdenum (moly).

- Material: Mn14, Mn14Mo1, Mn18Mo2

- Hardness: Overall hardness. Around 45-50 HRC

- Working life: We can promise at least crush 6500 tons of scrap metal

- Price: Check with our engineers

- Suitable material: Scrap metal

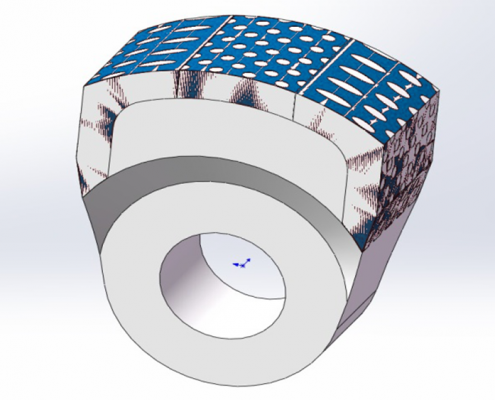

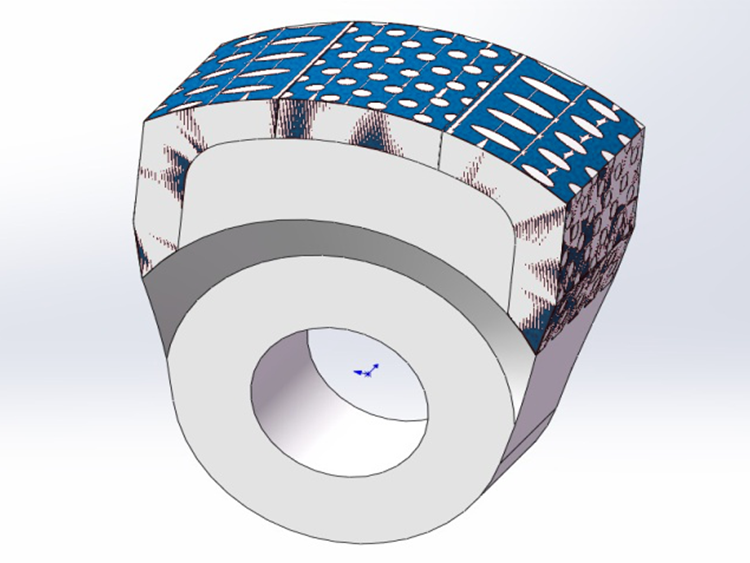

Ceramic Inserts Shredder Hammers

Ceramic Inserts Shredder Hammers

Based on customer inquiries, Hunan JY Casting has developed two kinds of ceramic inserts shredder hammers: Martensitic steel+Ceramic and Manganese steel+Ceramic. Martensitic steel inserts ceramic hammers have a higher hardness than manganese steel inserts hammers. The specific choice depends on the actual use of the customers.

- Material: Martensitic steel+Ceramic and Manganese steel+Ceramic

- Hardness: local hardness

- Working life: based on crushed material

- Price: Check with our engineers

- Suitable material: Scrap metal

TIC Inserts Shredder Hammers

TIC Inserts Shredder Hammers

This is a new material for shredder hammers. We use titanium carbide rods to insert the manganese steel matrix. Usually, this material is used in the cement industry. In crushing scrap metal, there is not enough feedback to tell the situation.

- Material: TIC Rods+ Manganese Steel

- Hardness: local hardness

- Working life: based on crushed material

- Price: Check with our engineers

- Suitable material: Scrap metal