Ceramic Inserts Wear Parts

Hunan JY Casting is an innovation leader for wear parts serving the mining, aggregate, cement, coal, and oil & gas industries. We’re committed to engineered solutions that provide long-term performance, low maintenance, and more machine uptime. Wear parts incorporating ceramic inserts offer clear advantages vs regular steel alloys. Drawing parallels to the animal kingdom, shark skin is one of the toughest materials on earth using a matrix of tiny, hard, tooth-like structures. Hunan JY Casting manufacturers a range of ceramic inserts wear parts with excellent armor-like properties.

Advantages of ceramic inserts wear parts

- Manufactured with a special casting process and heat treatment process.

- Alloy Matrix (MMC) bonds the ceramic properties for the best of both worlds. It combines ceramic hardness and alloy ductility/toughness.

- Ceramic particle hardness is very high, about HV1400-1900 (HRC74-80), it has high wear resistance, corrosion resistance, and heat resistance properties.

- Less intervention and reduced maintenance cost.

- Customers report 1.5x to 10x longer wear life using ceramic inserts compared to the parts they replaced.

Ceramic Inserts Blow Bars

Ceramic Inserts Blow Bars Materials

◆Chrome & Chrome+Ceramic

◆Martensitic steel & Martensitic+Ceramic

◆Manganese steel & Manganese+Ceramic

Ceramic Inserts Blow Bars Application

◆Quarrying, mining, and recycling.

Ceramic Inserts Blow Bars Advantages

◆More wear-resistant, as long as a double lifetime of normal blow bars.

Ceramic Inserts Chute Liners

Ceramic Inserts Chute Liners Materials

◆Chrome white iron & Chrome+Ceramic

Ceramic Inserts Chute Liners Application

◆Mining chutes

Ceramic Inserts Chute Liners Advantages

◆More wear-resistant, up to double or triple lifetime of normal chrome liners

◆More impact-resistant than pure ceramic liners

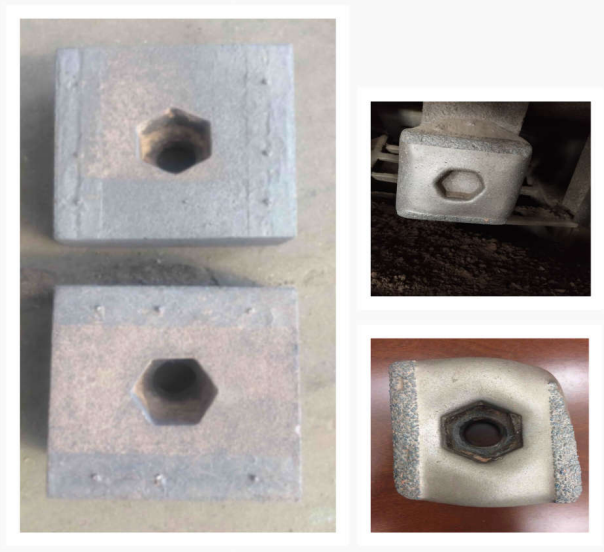

Ceramic Inserts Anvils

Ceramic Inserts Anvils Materials

◆High chrome white iron & Chrome+Ceramic

Ceramic Inserts Anvils Application

◆VSI crusher impellers and anvils.

Ceramic Inserts Anvils Advantages

◆More wear-resistant, as long as a double or triple lifetime of normal impeller or anvils.

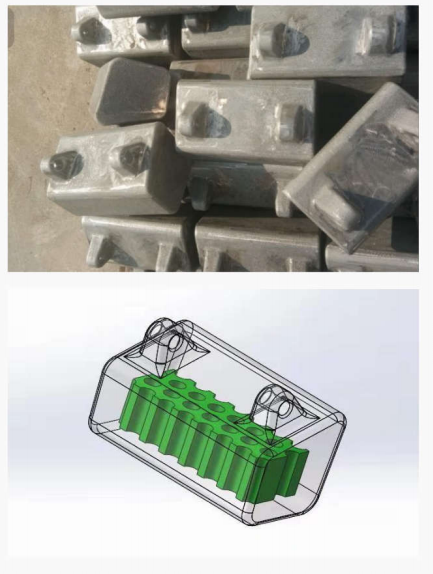

Ceramic Inserts Crusher Hammers

Ceramic Inserts Crusher Hammers Materials

◆Chrome & Chrome+Ceramic

◆Martensitic steel & Martensitic+Ceramic

◆Manganese steel & Manganese+Ceramic

Ceramic Inserts Crusher Hammers Application

◆Limestones crushing in quarry, mining and cement plant

Ceramic Inserts Crusher Hammers Advantages

More wear-resistant, as long as the double or triple lifetime of normal hammers.

Ceramic Inserts Hammer Head

Ceramic Inserts Hammer Head Materials

◆Chrome white iron+Ceramic

Ceramic Inserts Hammer Head Application

◆Crushing shales and coal gangues

Ceramic Inserts Hammer Head Advantages

◆ More wear-resistant, as long as the double or triple lifetime of normal hammer.

Ceramic Inserts Hammer Head

Ceramic Inserts Mill liners Materials

◆Chrome & Chrome+Ceramic

Ceramic Inserts Mill liners Application

◆Mining and Cement plant

Ceramic Inserts Mill liners Advantages

◆More wear-resistant, as long as a double life time of normal liners

Ceramic Inserts Rollers

Ceramic Inserts Rollers Materials

◆Chrome white iron+Ceramic

Ceramic Inserts Rollers Application

◆Fine grinding in cement plant

Ceramic Inserts Rollers Advantages

◆ More wear-resistant, as long as a double lifetime of normal rollers.