What is crusher wear parts?

Crusher wear parts, which are also called crusher wearing parts. They are the most important parts of the crusher. Among the components of the crusher, the parts directly used for crushing the stone are collectively referred to as the crusher wear parts.

Types of crusher wear parts

Different types of crushers have different crusher wear parts.

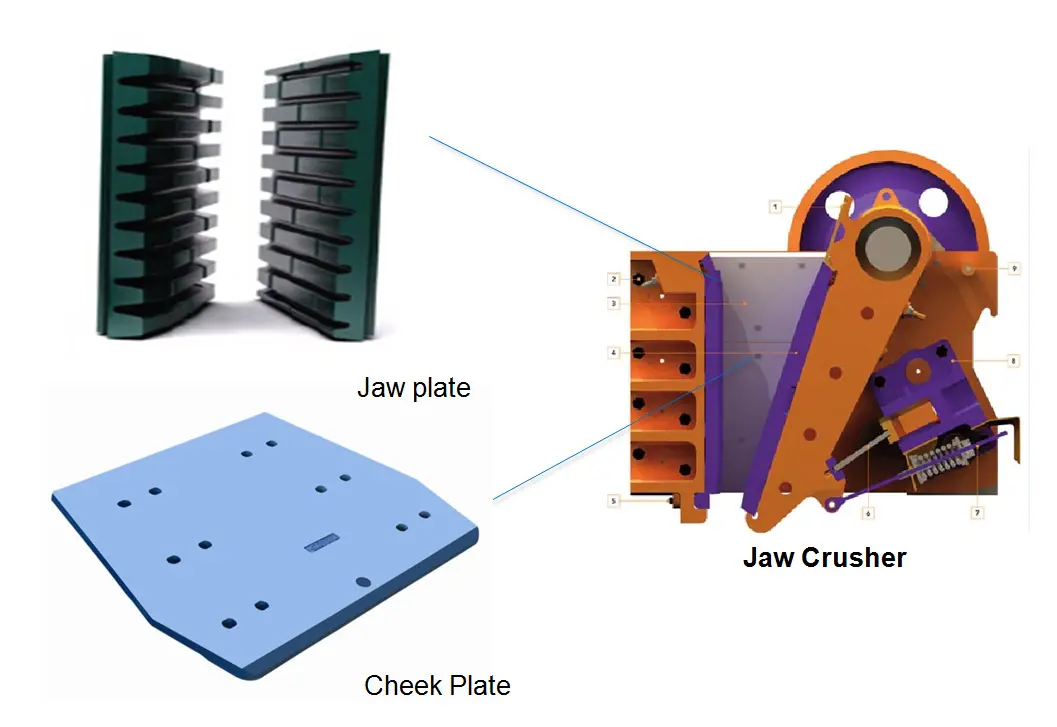

Jaw Crusher Wear Parts

In a jaw crusher, the common wear parts are:

- Fixed jaw plate

- Movable jaw plate

- Cheek plates

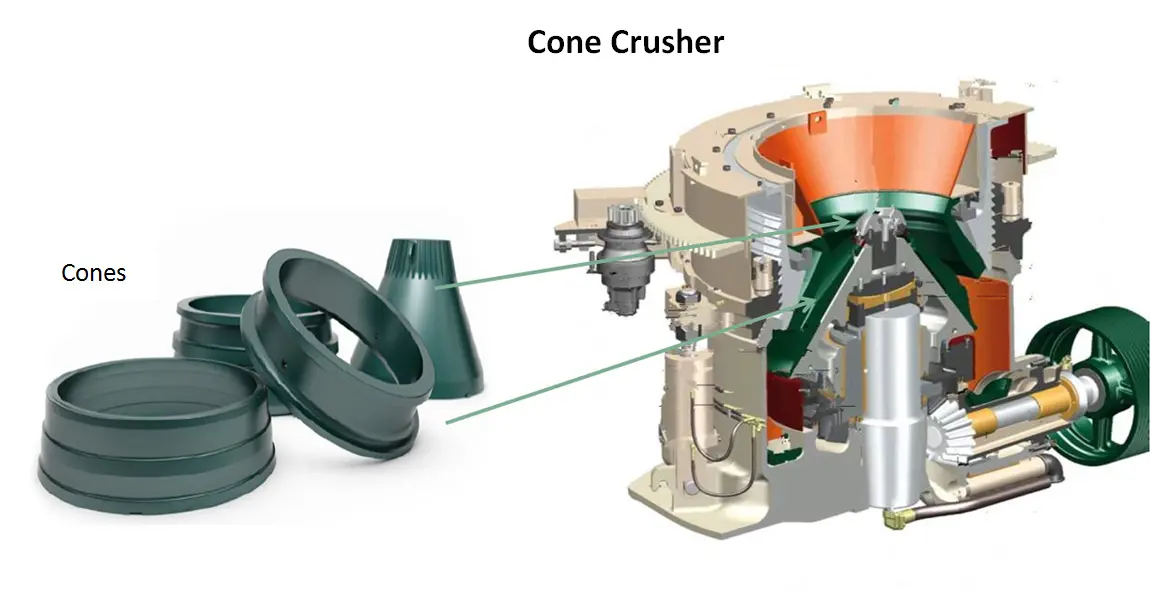

Cone Crusher Wear Parts

In a jaw crusher, the common wear parts are:

- Mantles

- Concaves

- Torch Rings

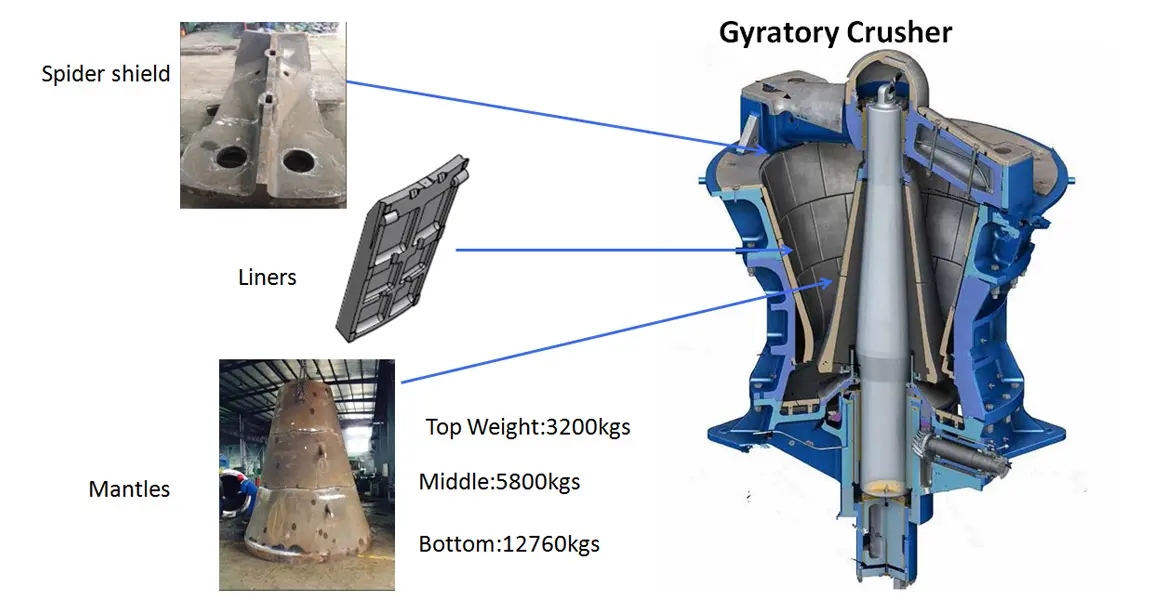

Gyratory Crusher Wear Parts

In a gyratory crusher, the common wear parts are:

- Mantles

- Concave Segments

- Spider Shield

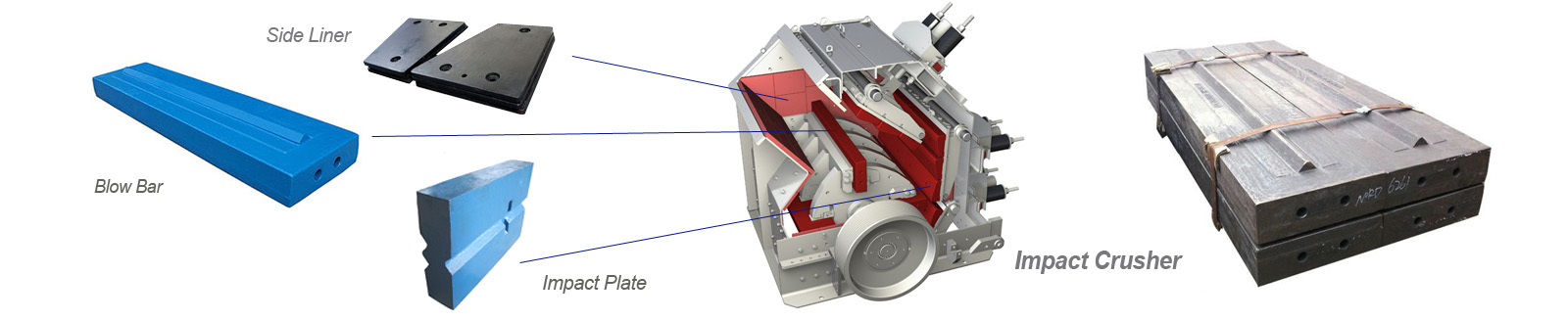

Impact Crusher Wear Parts

In an impact crusher, the common wear parts are:

- Crusher Blow Bars

- Impact Plates

- Side Plates

Crusher wear parts material selection

Different types of crusher wear parts, the materials are also different.

Materials for jaw crusher wear parts:

- Fixed jaw plate → Manganese steel, which includes Mn14, Mn18, and Mn22

- Movable jaw plate → Manganese steel, which includes Mn14, Mn18, and Mn22

- Cheek plates → Manganese steel, which includes Mn14, Mn18, and Mn22

There are also some special materials for jaw wear parts. For example, TIC rods + Manganese steel is widely used in casting wide-tooth jaw plates when crushing hard stone.

Materials for cone crusher wear parts:

- Mantles → Manganese steel, which includes Mn14, Mn18, and Mn22

- Concaves → Manganese steel, which includes Mn14, Mn18, and Mn22

- Torch Rings → Manganese steel, which includes Mn14, Mn18, and Mn22

There are also some special materials for cone wear parts. For example, Modified manganese steel is widely used in casting mantles and concaves when crushing copper mine; TIC rods + Manganese steel is used in casting mantles and concaves when crushing hard stone; Alloy steel is also used in casting mantles and concaves when those liners use to magnetic separation.

Materials for gyratory crusher wear parts:

- Mantles → Manganese steel, which includes Mn14, Mn18, and Mn22

- Concave Segments → Manganese steel, (which includes Mn14, Mn18, and Mn22), chrome steel, alloy steel

- Spider Shield → Manganese steel, which includes Mn14, Mn18, and Mn22

There are also some special materials for gyratory wear parts. Based on customer inquiries, some foundries also supply modified manganese steel mantles and TIC inserts mantles for gyratory crushers,

Materials for impact crusher wear parts:

- Crusher Blow Bars → Manganese steel, chrome steel, ceramic inserts, martensitic Steel

- Impact Plates → Chrome steel

- Side Plates → Chrome steel

Crusher wear parts price

As casting products, the price composition of crusher wear parts is as follows:

Pattern fee + Raw material fee + Casting fee + Heat treatment fee + Machining fee + Printing fee + Package fee

- Pattern fee. Normally, the patterns are wood patterns, price around USD0.45 to USD0.65 per kg in China market;

- Raw material fee. Different foundries use different raw materials. The price difference is huge. Some foundries use recycled materials, the price is very low;

- Casting fee, heat treatment fee, and machining fee. They are electricity bills;

- Printing fee and package fee based on customer inquiries.

How to decrease crusher wear parts price?

- Choose the foundry who have the inquiry wear parts patterns;

- Choose the right raw material;

- Create a bulk order plan. The largest quantity, the cheapest price.

Crusher Wear Parts Suppliers In China

Everyone knows that China is the biggest industry product manufacturer in the world. Back to crusher wear parts supply chain, most of the famous brand’s crusher wear parts OEM foundries located in China. Right now, let us show you the famous crusher wear parts suppliers in China.

Mayang Precise Foundry

In 1985, the predecessor of Mayang Company —Wuyi Mayang Precision Casting Factory was established, this company is specialized in producing high-manganese steel, alloy steel, high chromium cast iron, carbon steel, heat-resistant steel, and other castings, At first establishing stage the company makes a tremendous investment in including the industrial plants of 130,000 square meters.

JYS Casting

JYS Casting is manganese steel, chrome steel, and alloy steel cast foundry. Its feature products include Crusher Wear Parts, Shredder Wear Parts, Mill Liners, Apron Feeder Pans, Electric Rope Shovel Parts, and Crusher Spare Parts.

JYS Casting foundry covers an area of 40 acres, a total investment of 70 million yuan. It specializes in the production, sales, and research of wear-resistant, high temperature-resistant, corrosion-resistant materials with an annual production capacity of over 15,000 tons.

Great Wall Foundry

The 1985 year, Great Wall Foundry started with melting metal scraps into steel blocks and sold them to bigger steel makers as melting material. This foundry is able to produce 8,000 tons of castings a year at full capacity, and our new plant, which is due to open in late 2020, would increase our capacity to 15,000 tons annually.

Nanjing Manganese Manufacturing Co.; Ltd

Nanjing Manganese Manufacturing Co.; Ltd, which had specialized in casting crusher wear parts, jaw crusher parts, cone crusher parts, impact crusher parts, vsi crusher parts, roll mill parts and other manganese, chrome casting parts over 20 years. This foundry locates in Gangtang town, Shuangfeng city, Hunan province.

Hunan JY Casting

Back to our foundry, we are a material casting foundry, which specialized in manufacturing crusher wear parts, shredder wear parts, mill liners, and other wear parts by manganese steel, chrome steel, and alloy steel.

Every year, we supply more than 10000 tons of wear parts for our oversea customers. If you want to find a crusher wear parts factory from China, you can contact us freely.