The paper shows Hunan JY Casting’s cone crusher liner heat treatment standard. Before starting to introduce our standard, we need to know some concepts:

What are cone crusher liners?

Cone crusher liners include cone crusher mantles and concaves.

What are the materials for cone crusher liners?

Because different materials need different heat treatments, so we need to know the materials for cone crusher liners:

- JY510. It is low-grade Hadfield manganese steel.

- JY520. Low-grade manganese steel with molybdenum alloying.

- JY610. Low-grade manganese steel with chromium alloying.

- JY710. High-grade manganese steel with chromium alloying.

- JY720. High-grade manganese steel with chromium alloying.

- JY750. High-grade special manganese steel.

- JY770. High-grade special manganese steel with molybdenum alloying.

Furnace Requirements

There are some requirements:

- The minimum distance between two castings is 1.5 times the maximum wall thickness of the casting.

- For castings produced in JY720, JY750, and JY770, the limit of the load height is established as follows: Maximum thickness ≤ 120mm: maximum stacking is 3 casting parts; Maximum thickness>120mm: maximum stacking is 2 casting parts; The maximum thickness is considered the thicker casting of the loading.

- In any circumstance, the flame cannot touch the surface of the castings. The operator shall verify the flame prior to starting the heating process.

- The minimum distance between castings and the inner walls of the furnace shall be respected as follow: Minimum distance from the roof>300mm; Minimum distance from side furnace wall> 300mm; Minimum distance from back wall>200mm; Minimum distance from furnace door>400mm.

Cone Crusher Liners Heat Treatment Process

The heat treatment process of cone crusher liners is as follows:

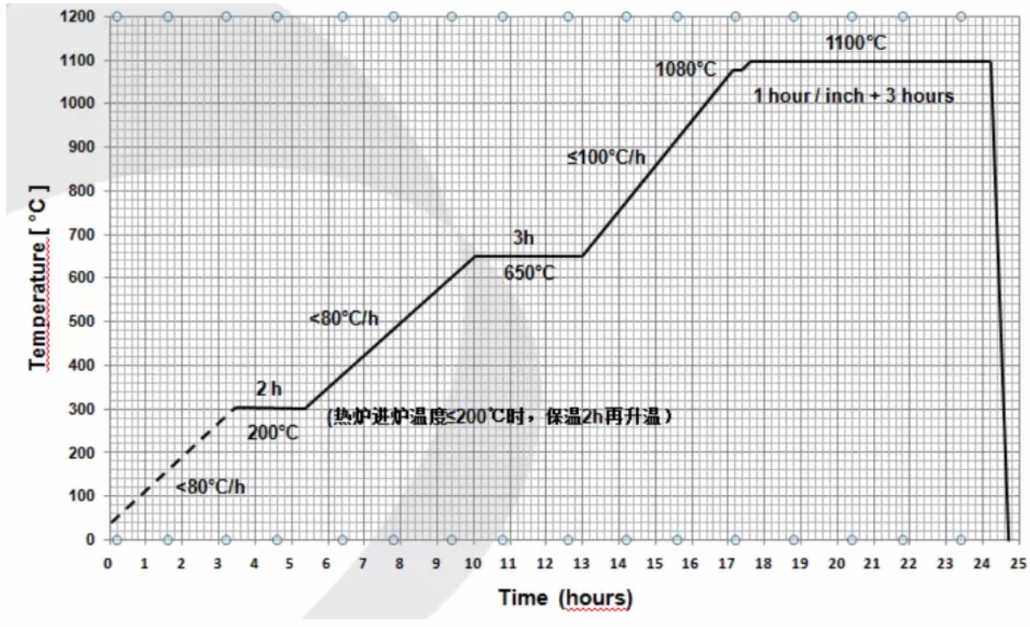

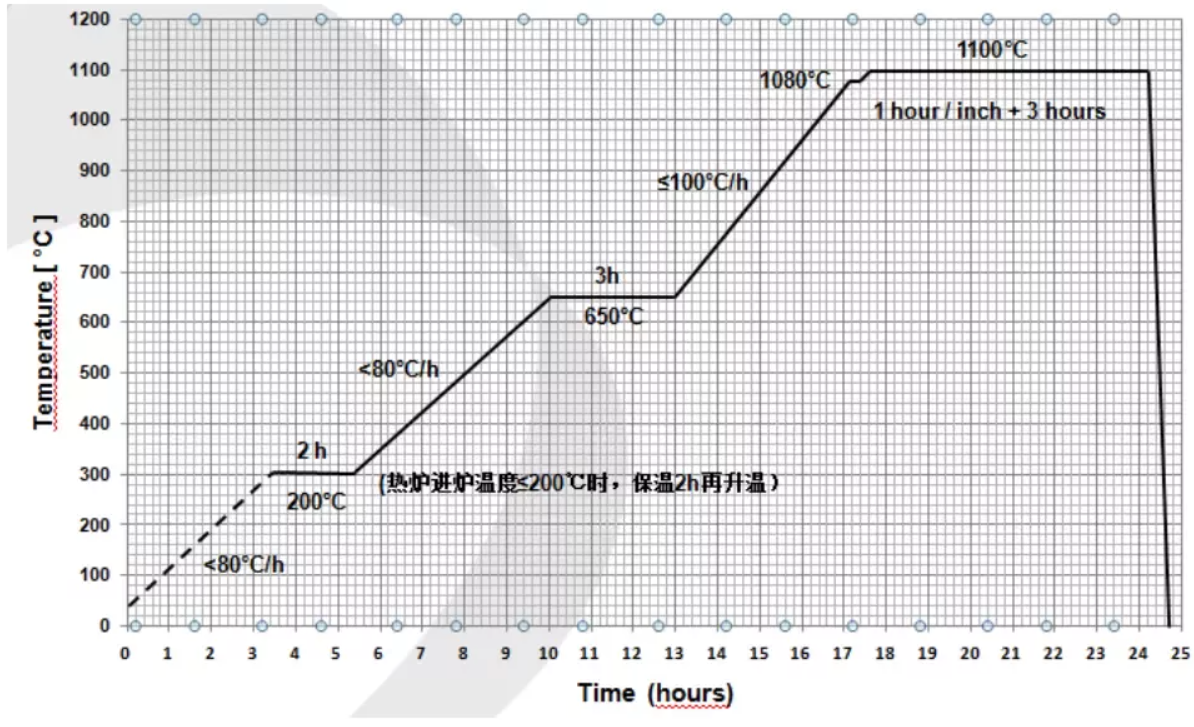

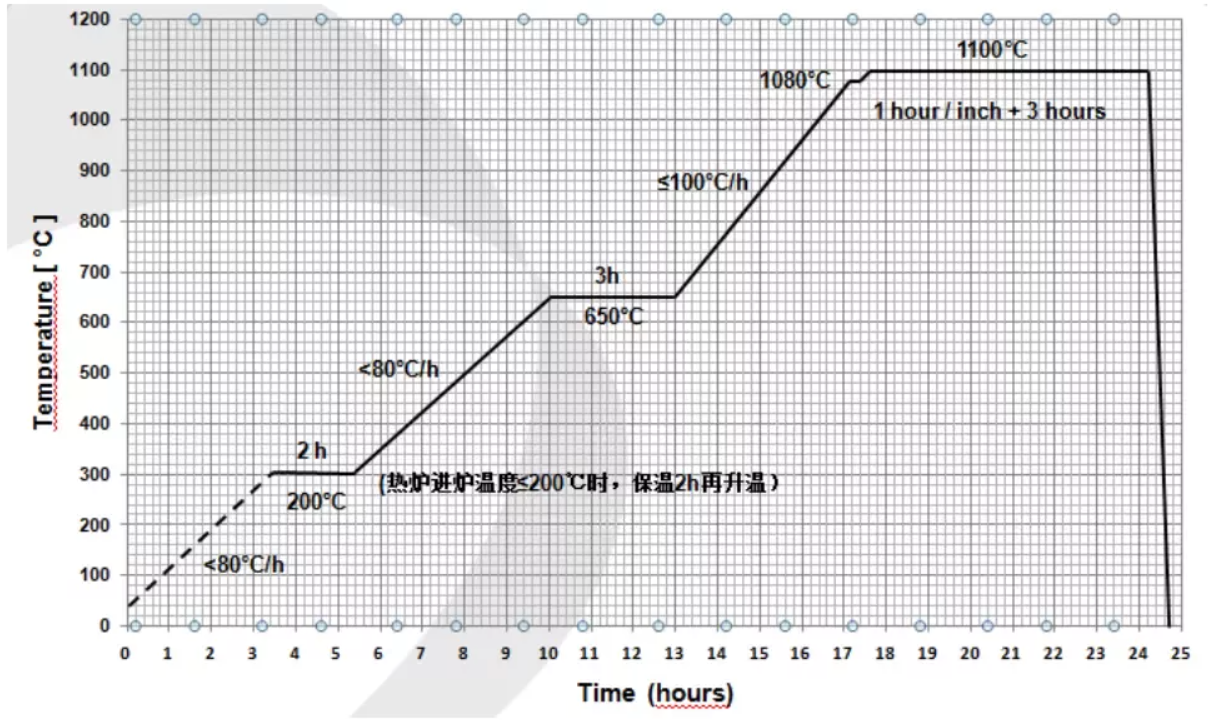

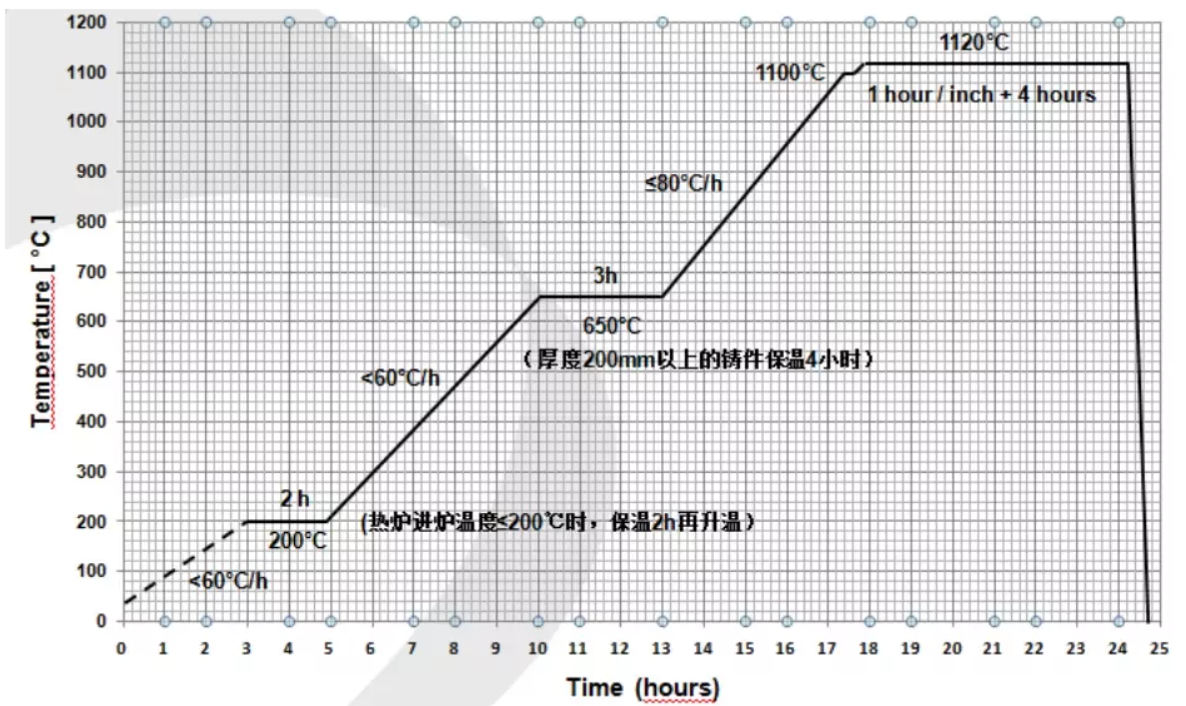

| Material | Max. Thickness (mm) | Heating Rate(℃/hour) | Max. Loading Temperature (℃) | Soaking Temperature (℃) | Soaking Time |

| JY510 JY520 JY525 JY610 JY710 |

<150 | Curve A | 200 | 1100 | 1 hour/inch + 3 hours |

| ≥150 | Curve B | 200 | 1120 | 1 hour/inch + 4 hours | |

| JY720 JY750 JY770 |

<150 | Curve B | 200 | 1120 | 1 hour/inch + 4 hours |

| ≥150 | Curve C | 200 | 1120 | 1 hour/inch + 4 hours |

Some notices:

- In the case of different alloy grades and thicknesses in the same loading, the more critical curve shall be considered. Curve C is more critical than curve B. Curve B is more critical than curve A.

- The soaking time is defined according to the thicker casting of the loading, and the measurement shall be performed at the maximum thickness of the casting.