One of the biggest factors in determining the life of a blow bar is the amount of wear that the piece experiences. In many cases, the amount of wear is a function of material type, rotor size, and desired reduction ratios. The resulting blow bar wear, combined with excessive wear, can significantly reduce the productivity of an impact crusher. In order to extend the life of the impact crusher blow bar, it is best to flip the bar regularly.

The Hardness of the Material

For the blow bar’s longevity, the hardness of the material is also important. A high chrome blow bar will be more resistant to wear and fracturing and can withstand high amounts of recycling materials. The refractoriness of the blow bar’s wear plate is an essential component in its life. Compared to manganese castings, this material is more environmentally friendly. If a crusher has high-chrome blow bars, it will have a shorter life and are more prone to splintering.

Another consideration is the rotor’s lifetime. A blow bar should be changed frequently to avoid unnecessary downtime. A faulty blow bar can cause lost production hours and lower efficiency. To reduce the risk of downtime, consider purchasing a refurbished or used crusher blow bar. Alternatively, consider purchasing a new crusher. A reliable and well-known supplier can offer used blow bars and parts. You can even exchange a worn out component.

Choose Chrome Blow Bars for Recycled Materials

High chrome blow bars are better suited to the abrasive feed material. They tend to last longer when crushing recycled materials, but the high chrome ones are prone to breaking. This makes it crucial to choose low chrome blow bars for such a high-abrasive application. If you are not using a heavy-duty blow bar, consider replacing it with a low-chrome blow bar.

The low-chrome blow bar is ideal for demolition and crushing concrete. This type of bar is ideally suited for crushing light aggregate and concrete. The high-chrome blow bar is the best for abrasive materials. It is also great for handling large feed materials, but it should be removed from the machine after crushing. A hybrid-chrome blow bar is better suited for abrasive materials such as limestone.

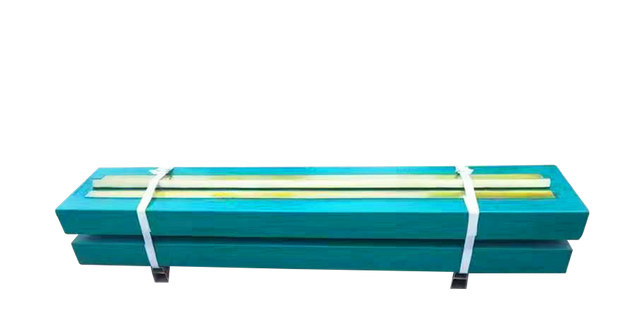

Impact Crusher Blow Bars

The life of the blow bar is critical for many applications. The lifespan of an impact crusher is the result of the impact blow bar’s wear resistance. An impact crusher blow bar’s lifespan is a function of the strength of the impact on the material it is crushing. The blow bar is the key component in the process of breaking material into smaller fragments. The higher the manganese content, the better the life expectancy of the blow bar. The material’s hardness, toughness, and resistance to abrasion also affect the blow bar’s lifespan.

Abrasive Feed Material

If you are using an impact crusher for abrasive feed material, the blow bars should be made from high-chrome or hybrid-chrome castings. High chrome is ideal for crushing concrete because it resists fracturing. Hybrid chrome is a good choice for limestone and other light to medium-hard materials. However, the high-chrome blow bars are not recommended for abrasive materials.

Use manganese castings for hard rock applications. Manganese is more wear-resistant than high chrome, but it is also more brittle. The lifespan of a manganese casting is shorter than a high-chrome or hybrid-chrome casting. Consider using manganese castings for hard rock applications such as granite, quartzite, and dolomite.

The material you are crushing will also affect the blow bar’s lifespan. Harder materials tend to wear out the blow bars faster than softer materials. Softer materials are easier on the blow bars and tend to last longer. The material’s hardness, toughness, and resistance to abrasion also affect the blow bar’s lifespan.

Environmental Conditions

The environment in which the impact crusher is used will also affect the blow bars’ lifespan. If the crusher is operated in a dusty or sandy environment, the blow bars will wear out faster than if it is operated in a dry, clean environment.

The temperature of the material being crushed will also affect the blow bars’ lifespan. If the material is too hot, the blow bars will wear out faster. If the material is too cold, the blow bars will be more brittle and may break.

The speed at which the material is being crushed will also affect the blow bars’ lifespan. The faster the material is being crushed, the more wear on the blow bars.

Operating Conditions

The way in which the crusher is operated will also affect the blow bars’ lifespan. If the crusher is operated at high speed, the blow bars will wear out faster. If the crusher is operated at low speed, the blow bars will be more brittle and may break.

Final Words

Finally, the size of the feed material will also affect the blow bars’ lifespan. If the feed material is too large, the blow bars will wear out faster. If the feed material is too small, the blow bars will be more brittle and may break.”