If your crusher is operating at capacity, the blow bar may need to be replaced after a certain amount of time. This is due to the fact that the bar is a vital component of the crushing machine. High-chrome bars can last for many years without replacement if they are properly maintained. However, if you are working on a smaller project, a change is more frequent than a rebuild.

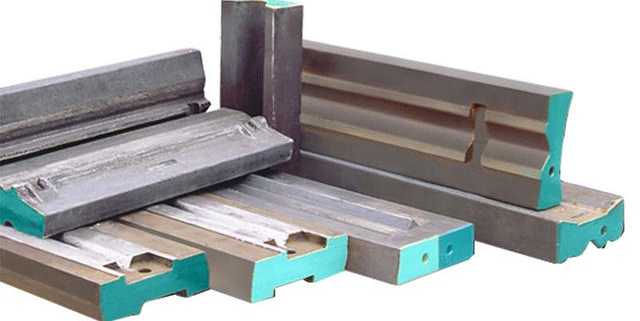

Different Types of Blow Bars

Depending on the material, there are several types of blow bars for your impact crusher. Some blow bars are softer than others. You can use one type for a certain type of material. You can also use two different types of blow bars, one for sand and another for gravel. The best kind to choose will depend on the type of feed material that the impact hammer will be processing. While it is possible to change the blow bar every six months, it can take a whole day.

Choosing the Right Crusher

High-chrome bars are designed to crush abrasive materials. They are ideal for crushing light aggregate and concrete. These types of bars are less expensive than high-chrome ones, but can’t crush as much material as the high-chrome versions. In addition, they can handle larger feed sizes. Make sure to remove tramp metal from the bar before replacing it. If you’re considering a change for your crusher, you should learn more about the different types and how to choose them for your needs.

Replacing Blow Bars

It’s important to have a full stock of blow bars for your impact crusher. As a result, the bar can wear out quickly in a crushing process. In addition to being a critical part of the crusher’s efficiency, the blow bar must be replaced at regular intervals. If a blow bar becomes worn out, the machine will stop working and you will lose valuable production hours. For this reason, you should replace the blow bar before the crusher stops working.

It is vital to know the type of material your impact crusher is capable of crushing. The type of impact crusher that you use depends on the types of materials you want to crush. A low-chrome blow bar is best for crushing aggregates and concrete. It has high-chrome, which is useful in recycling. In some cases, it will require you to replace the blow bar in order to keep your production rate high.

Replace Old Blow Bar

If you need to replace a blow bar in your crusher, you should follow a few guidelines. First, it’s crucial to have the correct type of crusher. If the blow bar is corroded, it will have to be replaced with a new one. If it has no rust, it will need to be replaced with a new one. Secondly, you should change the blow bar if you have to repair a damaged one.

While a blow bar is essential to impact crushers, it is not the only component that is prone to damage. The type of crusher blow bar you choose will depend on the materials you are crushing. Some blow bars have high manganese content, while others are made of a low manganese alloy. Regardless of the type of crusher, the blow bar should be changed regularly to prevent a breakdown in productivity.

A blow bar will need to be replaced as it ages. Depending on the type of material you’re crushing, you may need to change your blow bar regularly. A high-chrome bar is more likely to fracture a material while a low-chrome one will not. You’ll need to replace the blow bar if you’re using a lower-chrome blow bar. This will lead to lower productivity.

When to change crusher blow bars

There are 3 situations that need to change crusher blow bars:

- Normal wear. In order to avoid damage to the rotor, blow bars should be replaced before they are worn through.

- Blow bar break. When chrome blow bar crushes iron steel, it easily breaks; Some “problem” blow bars (Casting shrinkage cavity) also easily break; Other reasons results.

- When one face is used, the blow bar can be turned around to use the other face.

How to change crusher blow bars?

There are 6 steps to change crusher blow bars:

- Open the impact crusher as per the instruction manual;

- Switch off the system components and diesel generator;

- Secure the rotor;

- Visually inspect the wear limited on all blow bars;

- Visually check the blow bars for cracks and protrusions;

- Turn around or replace the blow bars as necessary

Notes on change crusher blow bars:

- For rough cleaning of crushing chamber, it is recommended to fill the crusher for several minutes with clean, coarse material;

- Always use suitable lifting gear and tack;

- At least two people should take part in installing and removing crusher blow bars;

- Improper replacement of the blow bars can lead to crusher damage;

- Completely extend the crusher gap before blow bar replacement in order to prevent a collision between the blow bars and toggle after new blow bars have been installed;

- Only operate the rotor if the blow bars have been correctly installed;

- Always replace blow bars in sequence;

- Before making the final setting, briefly operate the machine at the highest rotational speed, then check the wedge clamps; tighten the screws if necessary;

- Replace all blow bars even if only one of them broken;

- A non-secured rotor can lead to severe injuries, observe safety instructions;

- Always use conical spring washers with the clamping bolts of the tensioning devices. Retighten the clamping bolts after approx. two operating hours.

What Precautions Should You Take When Changing Crusher Blow Bars?

There are a few things you should keep in mind when changing your blow bars. First, it’s important to have the right type of crusher. If the blow bar is corroded, it will have to be replaced with a new one. If it has no rust, it will need to be replaced with a new one. Secondly, you should change the blow bar if you have to repair a damaged one.

You should also take precautions when changing your blow bars. Make sure to wear gloves and safety glasses. In addition, make sure to disconnect the power to the crusher before you begin working. Finally, be sure to clean up any debris that may have fallen into the crusher during the change.

Summary

Changing a blow bar is crucial for the productivity of an impact crusher. The right type of blow bar is vital for crushing different types of material. The type of blow bar used for the purpose of a specific crushing job is called the type of material to be crushed. A high-chrome one is suitable for crushing concrete. On the other hand, a low-chrome bar is suitable for a variety of aggregate materials. When you’re working with a large amount of material, you should always have a spare set of spare parts on hand.