Extending the life of cone crusher liners

Whilst wear replacement is a necessary feature of any crushing operation, there are steps you can take to extend the service life of crusher wear parts.

Always ensure the wear parts are fastened into the machine properly. Loose liners in cone crushers may damage the head or bowl.

It is also advisable that operators frequently look for holes, cracks, or flat spots, which could potentially damage the machine long-term or be an indication of another issue.

Further to that, you should track tonnages. As cone crusher liners wear, the operator threads the bowl inwards, bringing the bowl liner closer to the head which reduces the feed opening. The reduced feed opening may decrease crusher throughput at a cost; once that cost is greater than the price of the liner change you should consider changing the liners. At a glance, the liners may still have what you perceive as usable wear left, but at a lost tonnage that doesn’t benefit the plant.

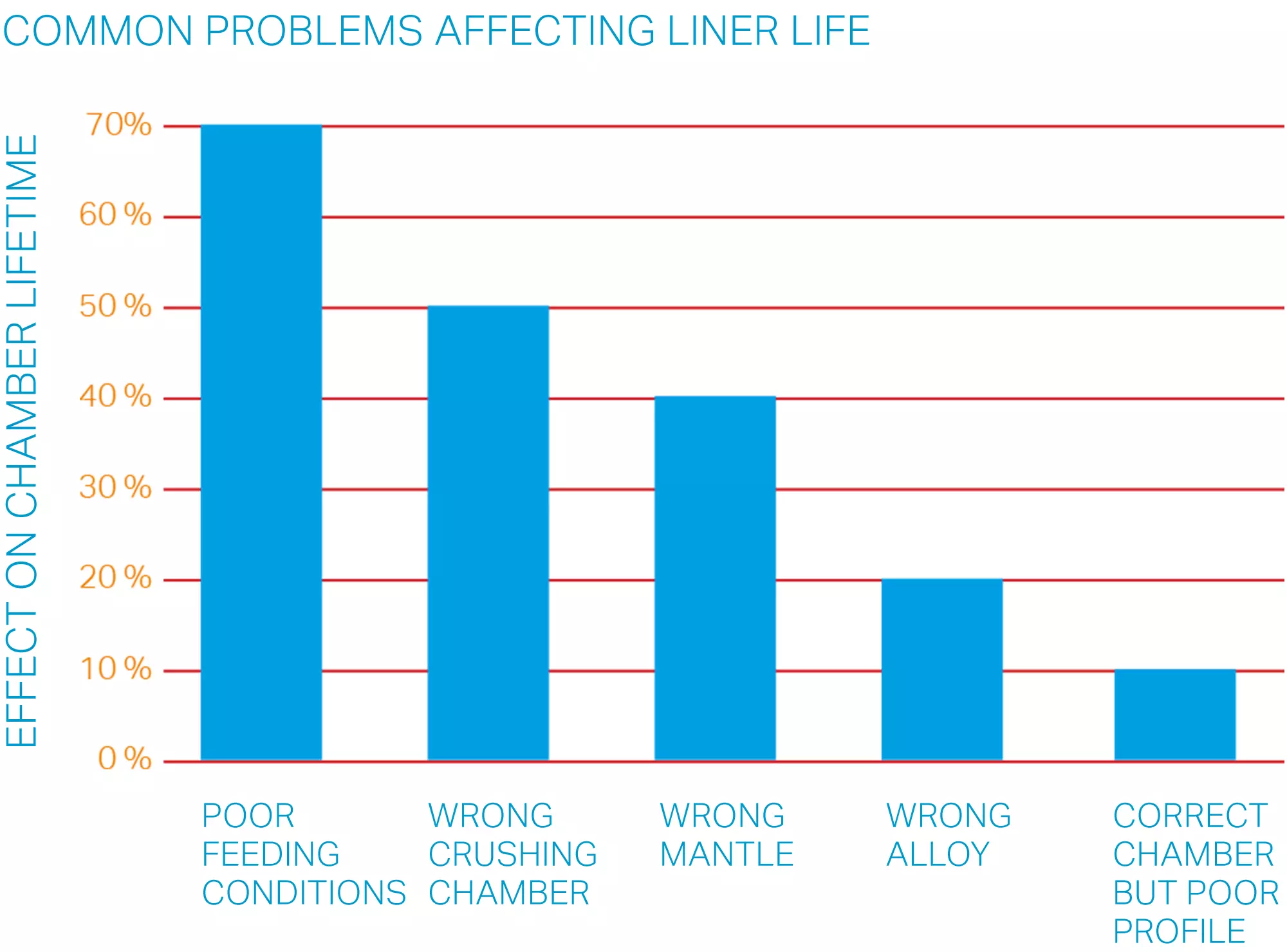

Maximizing the life of wear parts is a major consideration in any efficient crushing operation. Extending the life of liners in your cone crushers can significantly reduce maintenance costs and improve productivity, so it’s vital that any problems in this area are identified and minimized. Hunan JY Casting’s research has revealed five areas where liner life can be compromised.

Feed Conditions

The most common issue affecting liner life is poor feeding conditions. A poor feed can reduce the lifetime of your liners by up to 70% compared to a properly fed crusher. Feed problems often lead to uneven wear on your liners, meaning they have to be replaced even though large parts of the liners are still in good condition.

Crushing Chamber Issues

The other significant factors are related to the crushing chamber itself. Having the wrong crushing chamber – the fit between the concave and mantle, combined with the eccentric throw – can reduce liner life by 50%. Choosing the wrong mantle can cause a decrease of 40% while having the wrong alloy can reduce liner life by up to 20%.

The percentage figures are not mutually exclusive, so your liners may be affected by more than one of these problems.

What this research shows, is that there is often scope for making small changes to crushing, screening, or feeding processes that can yield significant productivity improvements. Hunan JY Casting provides a range of relevant services to customers around the world, including sampling analyses, condition inspections, and productivity services.

Leave a Reply

Want to join the discussion?Feel free to contribute!