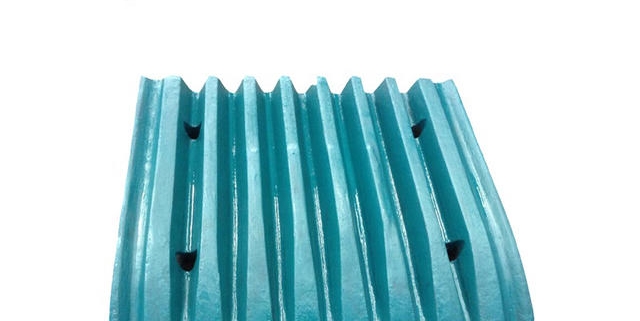

Properly maintaining crusher jaw plates can increase their lifespan and reduce costs. It’s important to understand why these parts wear out, and how to maintain them to extend their service life. Often, the materials that need crushing are irregular and of varying hardness and this create continuous friction. This friction increases as the moveable jaw moves in a vertical direction.

These causes wear to the jaw plates. Therefore, it is crucial to perform regular maintenance and repair to extend their service life. It is important to inspect the plates regularly to check for tooth valley and peak matches, and any damage to the teeth or valley should be repaired immediately.

Routinely Maintain Them

In order to improve the life of your jaw plates, it is necessary to maintain them regularly. The wear block is easily replaced, which allows you to keep your crusher up and running smoothly. If you notice any crack, gap, or flat area, make sure that it’s repaired or replaced before your next use. If you’re not sure if your jaw plate needs replacement, contact a manufacturer of new jaw plates to get the best value.

Replace Them as Necessary

One of the easiest ways to extend the life of your jaw crusher’s jaw plates is to replace them as needed. If you’re unsure of which part needs to be replaced, you can always buy new jaw plates from a regular supplier. Moreover, you should pay attention to the operation of your jaw crusher. The right care will help you prolong the life of your jaw plates. You should always check the peak and valley of your jaw plate to make sure that it’s not cracked, chipped, or flat.

Install Several Jaw Plates

In large jaw crushers, you can also install several blocks of jaw plates. This way, you can exchange the worn ones easily and extend their service life. In addition to these, if you want to improve the efficiency of your crushing process, you can even extend the life of the jaw plates by investing in better quality parts. If you’re looking to maximize your machine’s productivity, you can also invest in a high-quality, durable jaw plate.

Choose Only the Best Jaw Plates

As for the other parts of your crusher, jaw plates wear out primarily due to materials with different hardness and irregularity. This constant friction damages the jaw plates over time. Ensure that you buy only the best quality jaw plates from a reputable manufacturer to ensure the highest quality and safety of your equipment. If you’re not sure, consult with a professional. If you’re not sure, ask for a replacement.

The Jaws Should Be Symmetrical

The peaks and valleys of the movable jaw should be in line with the peaks and valleys of the fixed jaw. The movable jaw should be symmetrical in order to increase its crushing capacity. If it’s lopsided, you’ll need to change the movable jaw. If the lower part is severely worn, you can also turn the movable jaw. If there’s no difference in their shapes and sizes, the resulting material will be more uniform.

Maintain the Jaw Plate Teeth

Jaw plates are a very wearable part of a crusher. The jaws are continually squeezed by materials and impact against each other, making them the most wearable part of the machine. During this process, the teeth of the plates will wear out and require replacement. This means the jaw plate must be regularly checked to increase its life. The peak and valley of the teeth should match. When the movable jaw is worn, it is necessary to replace it.

Use the Right Lubricant

It’s important to use the right lubricant on your jaw crusher. This will prevent wear and tear on the machine. The wrong lubricant can cause damage to the movable jaw, resulting in a shorter life. Choose a high-quality, durable lubricant to extend the life of your machine. You should also regularly check the level of the lubricant and add more as needed.

Check for Damaged Bearings

The bearings in a jaw crusher are constantly under stress. This can cause them to become damaged over time. If you notice any damage, replace the bearings immediately. This will extend the life of your machine and prevent further damage.

Inspect the Frame Regularly

The frame of a jaw crusher is subject to a lot of stress. This can cause it to crack or break over time. Inspect the frame regularly for any damage. If you notice any cracks, replace the frame immediately.

Check for Worn Out Parts

Jaw crushers are subject to a lot of wear and tear. This can cause parts to become worn out over time. Inspect all of the parts regularly for any wear and tear. If you notice any damage, replace the part immediately.

Conclusion

The main part of the jaw crusher is the most wearable part. The movable jaw moves back and forth vertically, which creates constant friction. This causes damage to the jaw plates. But by conducting regular maintenance, you can extend the life of your plates and increase their performance. Inspecting the tooth valley and peak should match. If they’re cracked, the jaw plate needs to be replaced. Aside from regular cleaning, it also needs periodic adjustment.