In May 2021, we delivered 54 tons of Mircoalloy crusher liner to a Mongolian customer. He asks for a report that shows the difference between microalloy crusher liners and normal manganese crusher liners. A total of 80 pcs mircoalloy crusher liners and two additional casting test blocks were produced: 4JI0803 and 3JI1305, corresponding to the heat samples: 4JI0601 and 1JI1504 respectively.

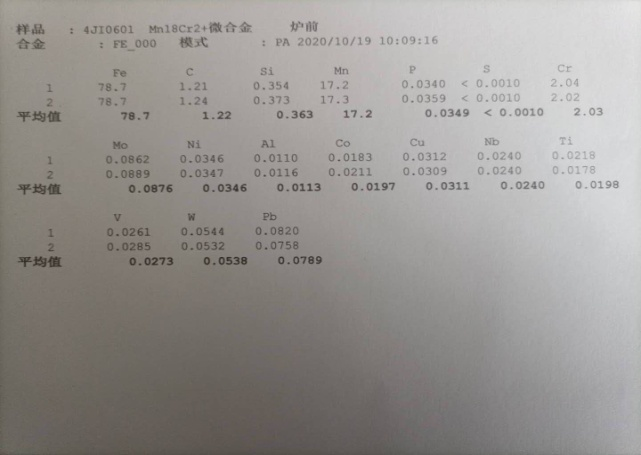

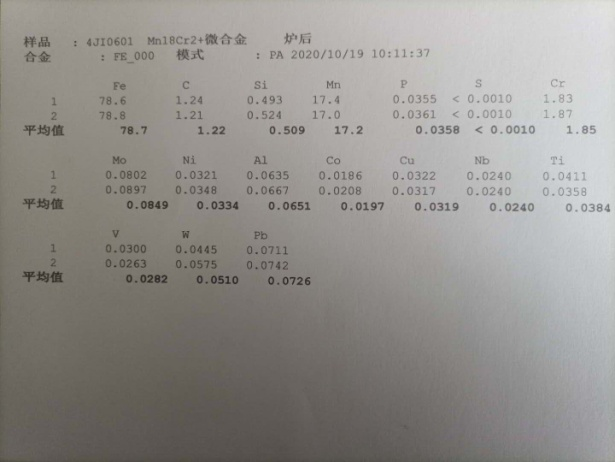

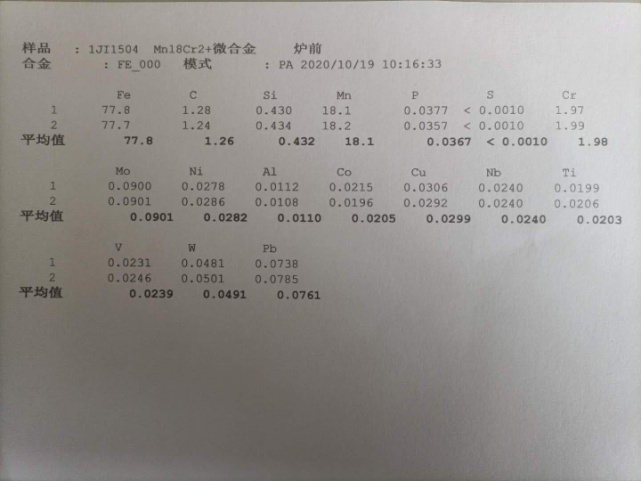

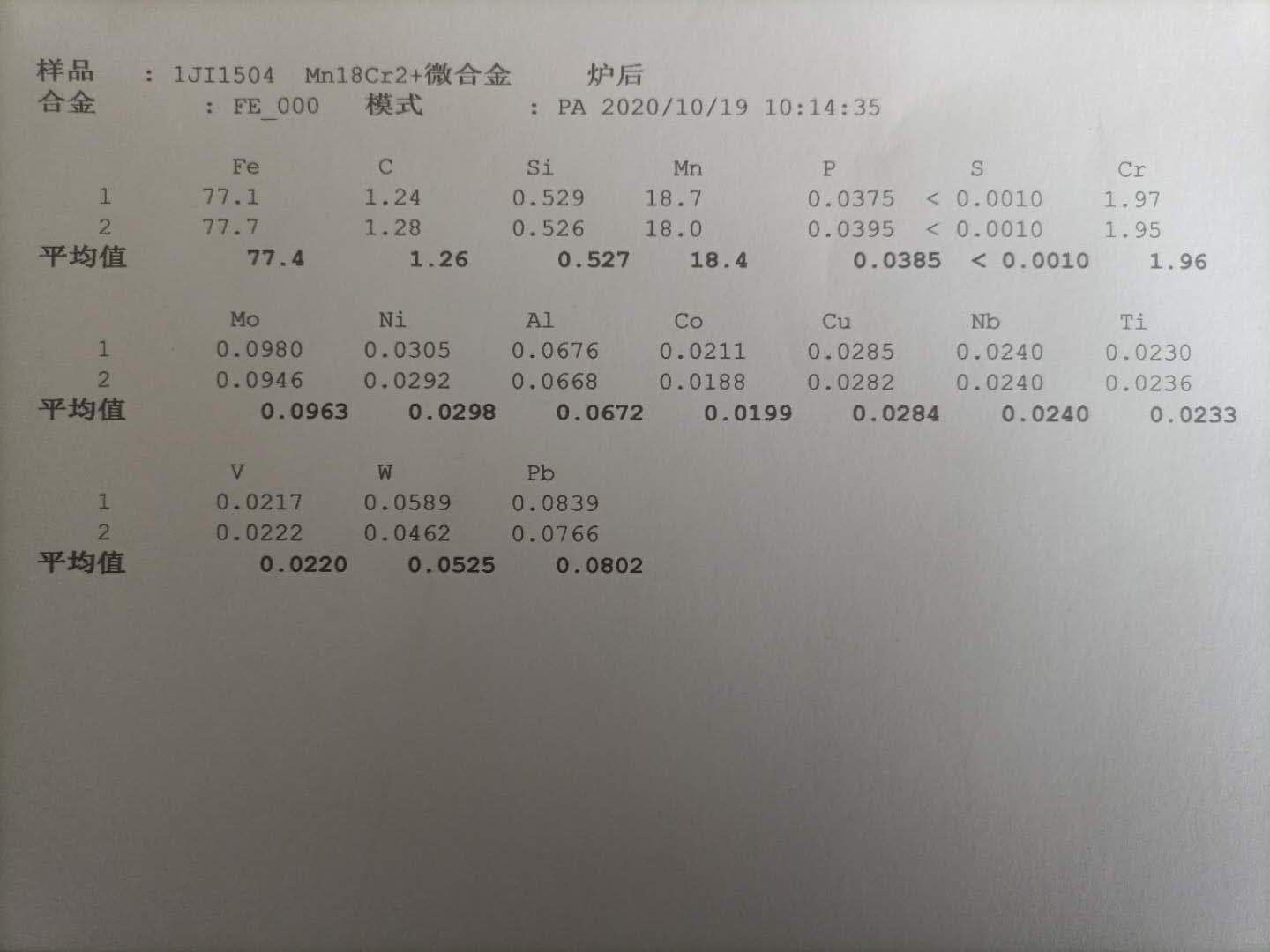

Chemical composition comparison

4JI0601 Ingredients before furnace

4JI0601 Ingredients after furnace

1JI1504 Ingredients before furnace

1JI1504 Ingredients after furnace

The microalloy is added to the ladle and cast into the casting after the molten steel is qualified. From the composition comparison of the samples before and after the furnace, the composition of the microalloy cannot be detected.

Mechanical properties comparison

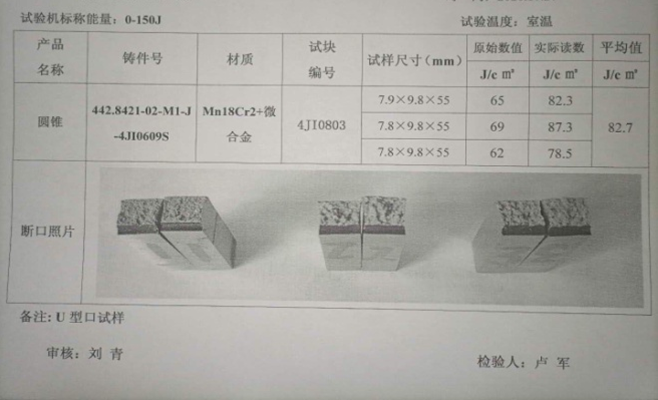

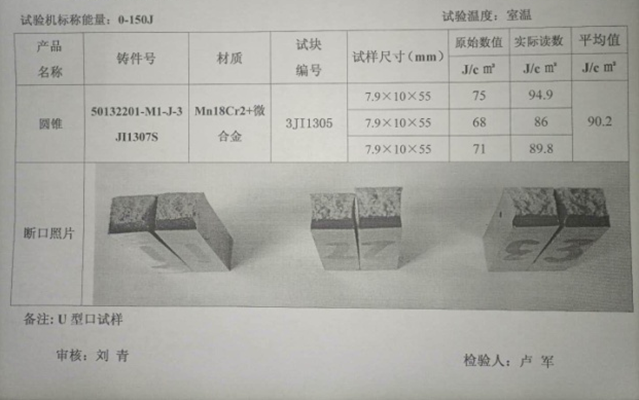

1.Impact test

4JI0803 impact test report

3JI1305 impact test report

The impact energy of normal Mn18Cr2 material is generally 120-150J/cm² and the impact energy of mircoalloy material is around 82-92J/cm².

The impact toughness is reduced after adding microalloy.

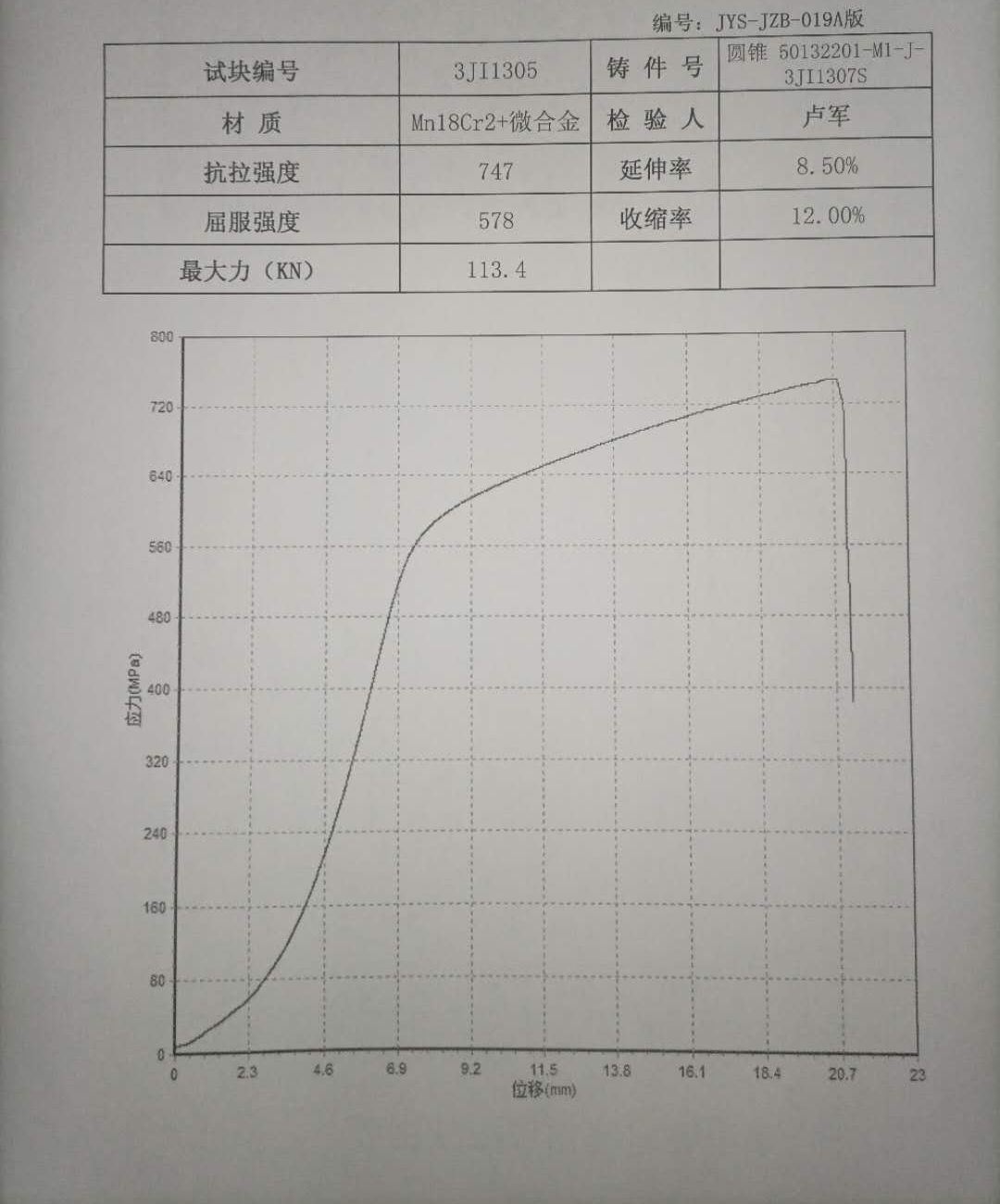

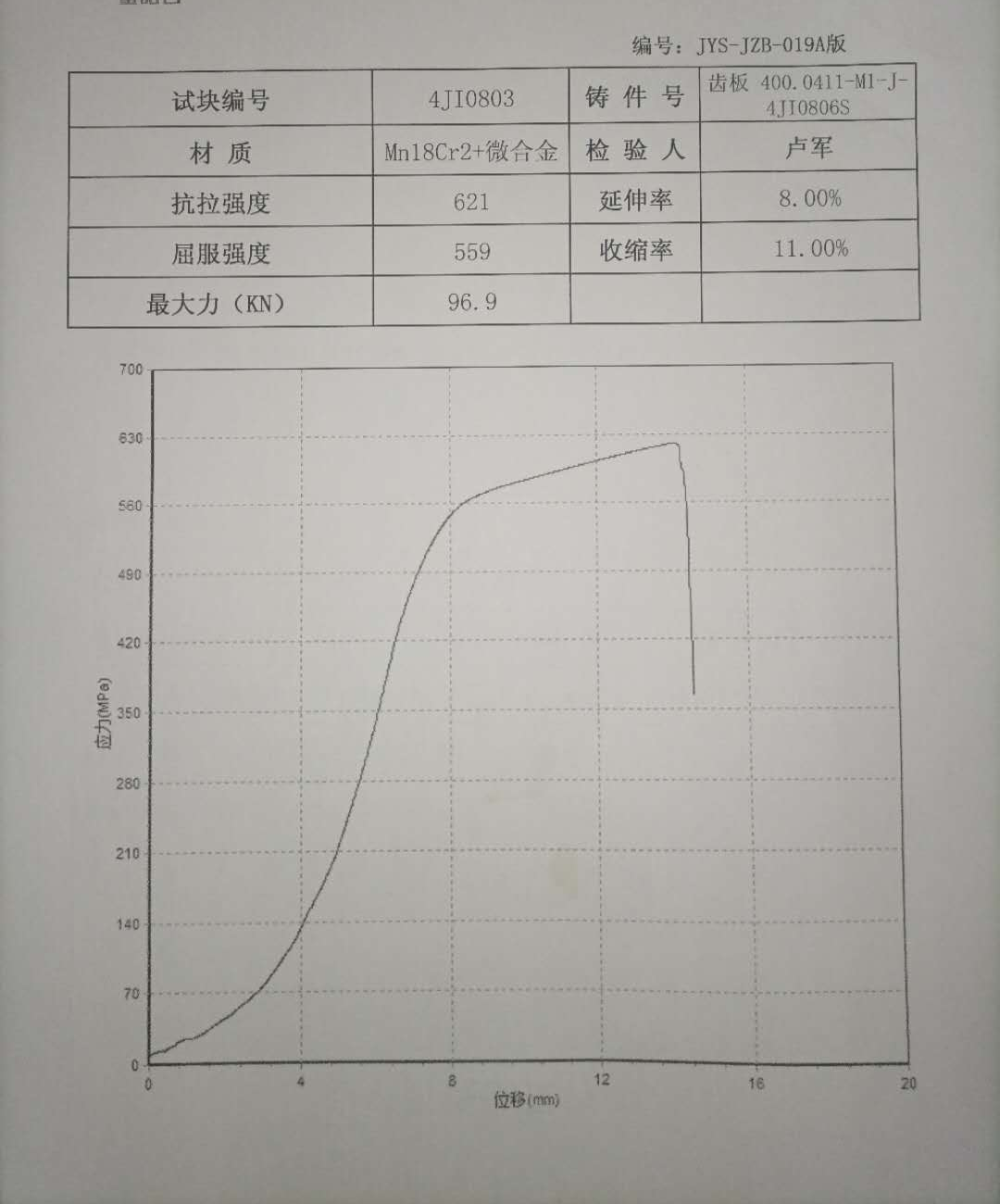

2.Stretching test

3JI1305 Mechanical Properties Report

4JI0803 Mechanical Properties Report

Mechanical Properties Report For Normal Mn18Cr2 Material:

- Tensile strength: 600-800MPa

- Yield strength: 520-580MPa

- Elongation and shrinkage: 22-28%

Mechanical Properties Report For Mircoalloy Material:

- Tensile strength: 600-800MPa

- Yield strength: 520-580MPa

- Elongation and shrinkage: 8-12%

From the test results, the tensile strength and yield strength are within the normal range, but the elongation and shrinkage are almost reduced by half, which also shows that the toughness has decreased.

In general: the toughness of the product after adding microalloy is reduced to improve the wear resistance.

Metallographic Analysis

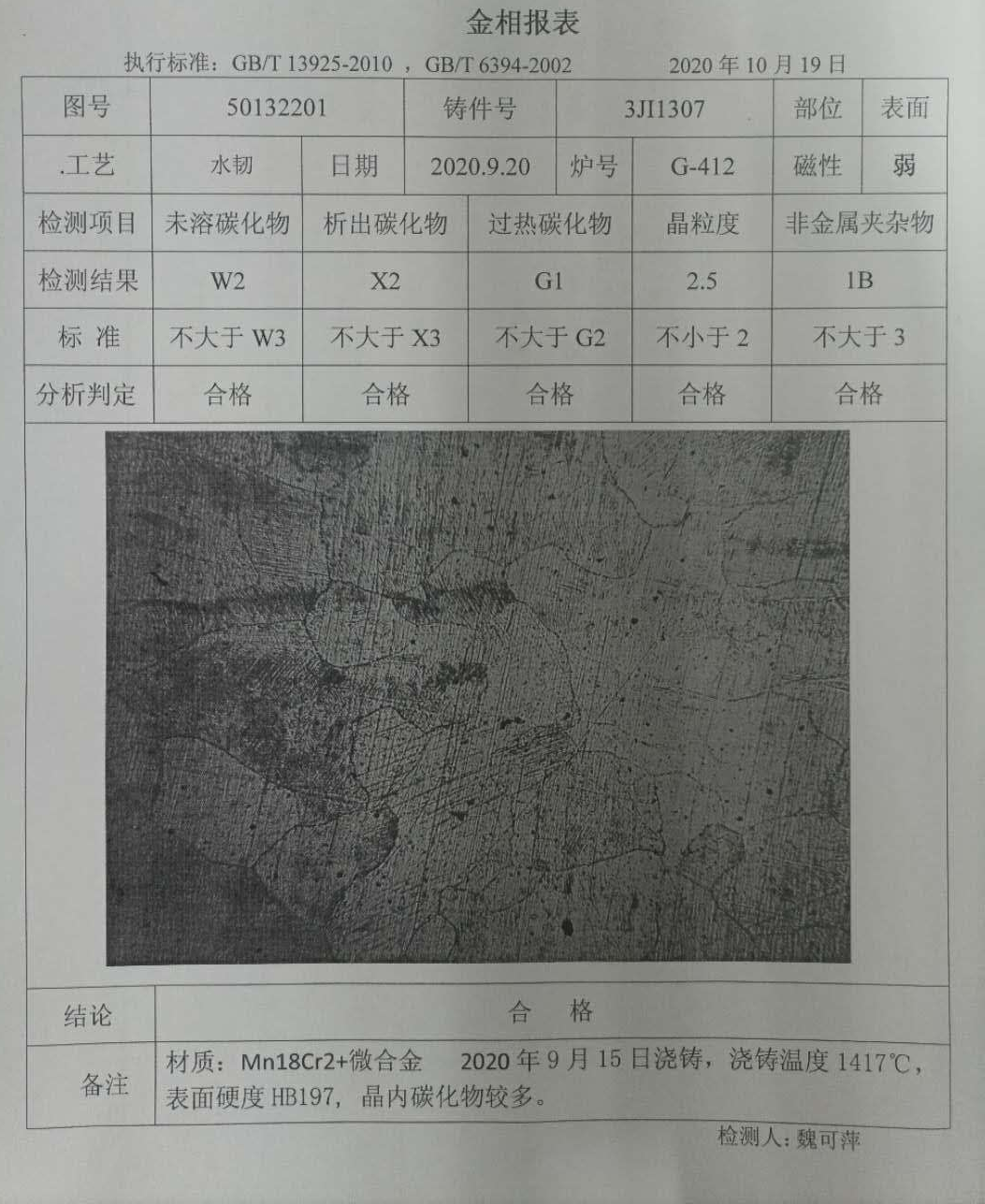

3JI1307 Metallographic Analysis Report

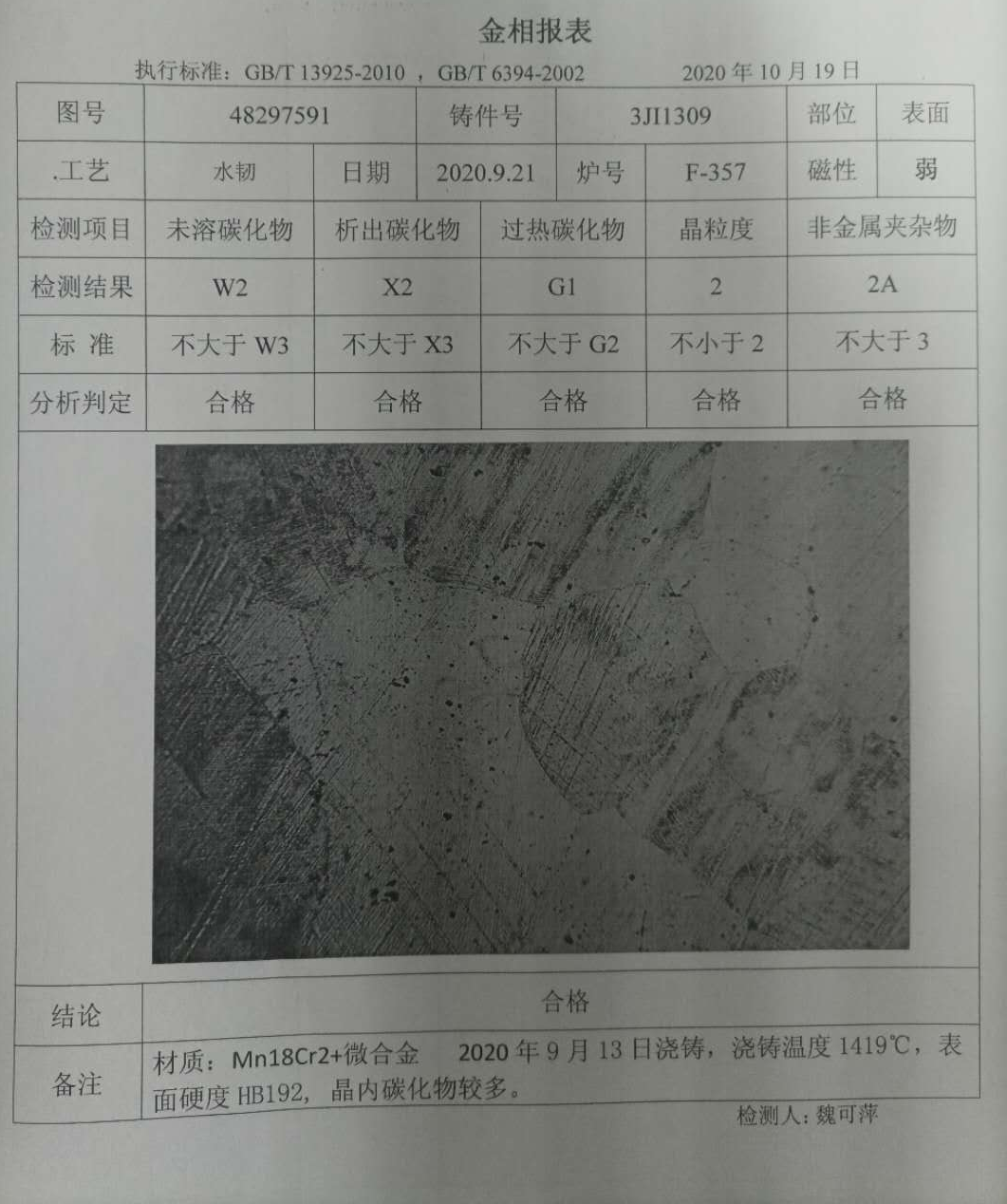

3JI1309 Metallographic Analysis Report

Compared with ordinary Mn18Cr2 products: the initial surface hardness is slightly higher, which can reach HB190 or above, the grain size is above 2 grades, and more dispersed carbides are formed inside the grains to improve wear resistance.

Conclusion

Compare with Mn18Cr2 crusher liners:

- The impact toughness is reduced after adding microalloy

- the toughness of the product after adding microalloy is reduced to improve the wear resistance

- Metallographic is better

- Based on customer feedback, the service life had increased by 30%