Premium Cone Crusher Liners

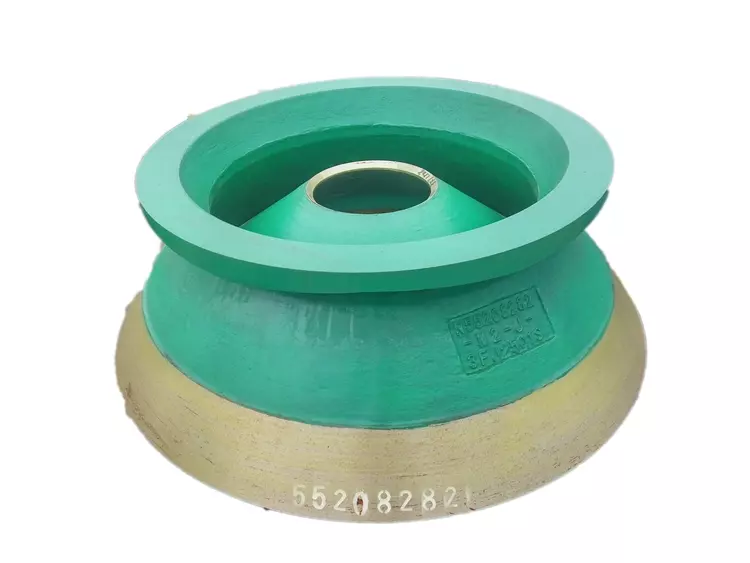

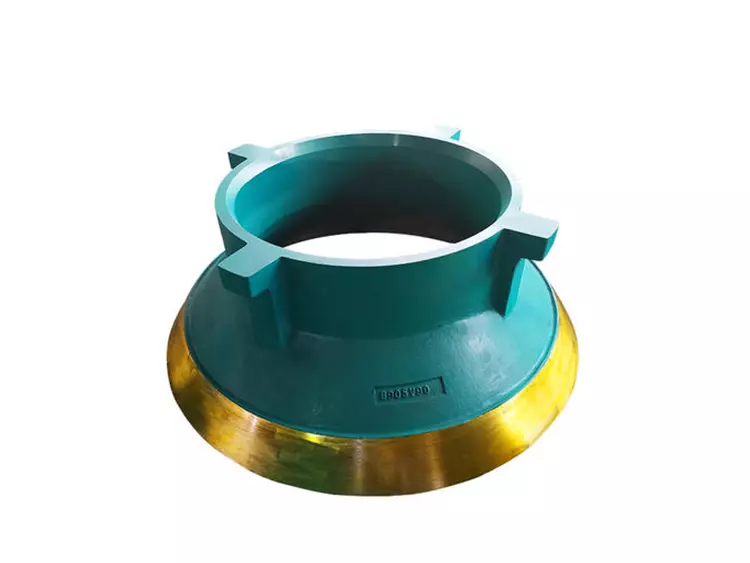

Cone crusher liners mainly wear parts in the cone crusher, which are included cone crusher mantle and cone crusher concave. Cone crusher mantle, which covers the cone head of the crusher to protect it from wear. It is the inner sacrificial wear liner that sits on the cone head. Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear. It is the outer sacrificial wear liner that sits inside the upper frame.

- Common Aliases: Cone crusher liners, Cone crusher wear parts, Manganese cone liners, Mantle and concave

- Main Material: Mn14, Mn18, Mn22, Manganese alloy steel, Manganese steel with TIC inserts

- Cast Methods: Lost foam casting, Sand casting, V-method casting

Cone Crusher Liners By Hunan JY Casting®

When it comes to cone crusher liners, Hunan JY Casting has been crushing the market for decades. No matter which brands cone crusher liners you want; No matter which material cone liners you need; No matter which cavity of cone crusher parts you inquiry; Hunan JY casting is your first choice! Through our application-driven, site-specific engineering capabilities, our offering of replacement cone crusher parts of most any origin has gained acceptance and earned the confidence of aggregate and mining operations around the world. In some cases, our manganese cone crusher liners lifetime 100% match the original wear parts; In more cases, our redesign cone liners lifetime is 1.5-2 times than the original wear parts.

Hunan JY Casting’s Cone Crusher Liners Suit:

Cone Crusher Liners FAQ

Which Material Hunan JY Casting manufactures for cone crusher liners?

Manganese Cone Crusher Liners

Manganese steel has been used in crushing applications for over 100 years, so it’s easy to take it for granted. It continues to be used because of the remarkable property that makes it ideal for wear liners: the harder you hit it, the harder it gets. Hunan JY Casting manganese steel cone crusher liners are made in our own materials that have been developed from the original Hadfield’s manganese steel specification. Our variations can provide unequaled toughness with excellent resistance to abrasion, which improves as the steelwork hardens in operation. Available in M14, M18, and special order M21 manganese steel we have a cost-effective solution to your specific requirements.

Modified Manganese Cone Liners

When crushing some material (such as copper mines stone), the standard manganese cone liners can not get a long lifetime. So, Hunan JY Casting engineers change the metallographic structure of the product by adjusting the ratio of manganese to carbon and adding some trace elements to obtain a more suitable life. Based on customer feedback, this modified manganese cone crusher liner’s lifetime can be 1.5 times that the standard material parts when crushing copper mine.

Manganese Steel With TIC Inserts Mantle and Concave

When crushing hard stone, the manganese steel mantle and concave can not work for a long time. Even the Mn22Cr2 cone crusher liner also can not get a good result. In order to solve this problem, the Hunan JY Casting engineer inlaid the titanium carbide rods on the working surface of the jaw plate. When crushing the stone, the high-hardness titanium carbide rod first touches the stone, thereby improving the hardness and wear resistance of the cone crusher parts.

How To Select The Right Material For Cone Crusher Liners?

Different crush stones need to choose different materials to suit. Such as soft and abrasion stones, the Mn14 is the best choice. Read more about our products →

How To Prolong Cone Crusher Liners Span Life?

Maximizing the life of wear parts is a major consideration in any efficient crushing operation. Extending the life of liners in your cone crushers can significantly reduce maintenance costs and improve productivity, so it’s vital that any problems in this area are identified and minimized. Hunan JY Casting’s research has revealed five areas where liner life can be compromised. Read more →

When & How To Change Cone Crusher Liners?

When & How To Change Cone Crusher Liners?

Liners that exceed their intended operating life will cause mechanical problems with the crusher. A liner that is pushed too long will flex and crack, and the flexing of a thin or cracked mantle will cause severe seat surface damage.

There is no 100% definitive way to determine when liners are worn out, but there are two indications it is time to change the liners. Read more →

What is the largest mantles or concaves you can cast?

The largest mantle or concave we can manufacture is 12 tons.

What is the cast method in your foundry?

We have two process lines: Wood pattern sand casting line and Lose foam casting line.