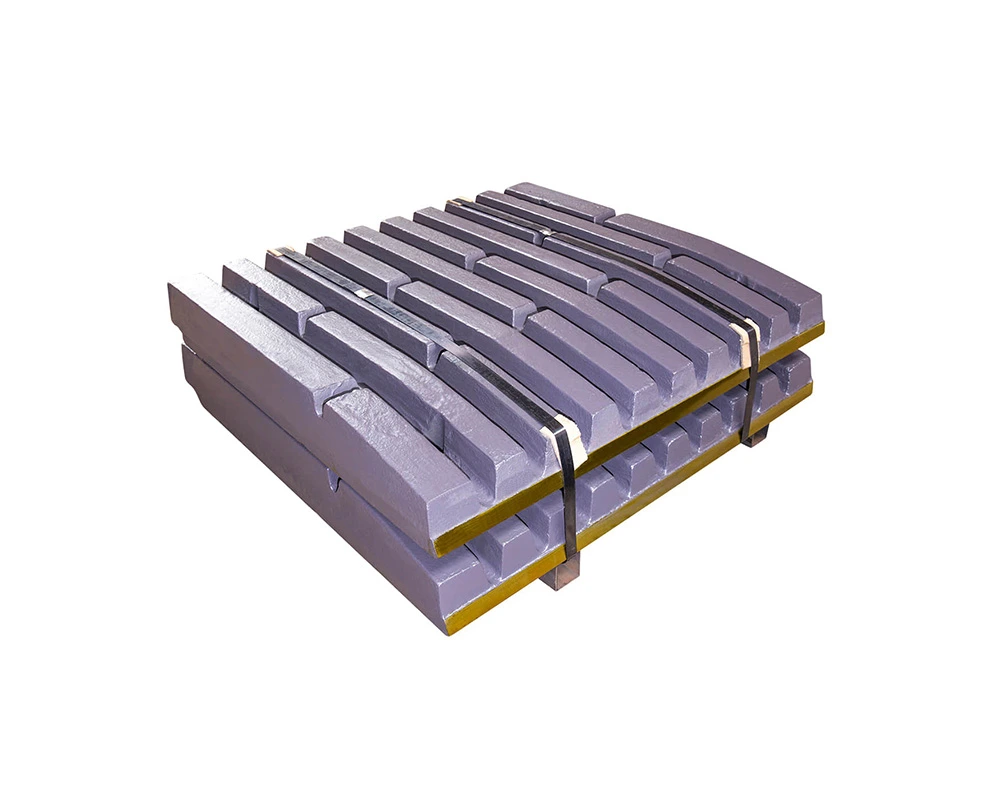

Premium Crusher Jaw Plates

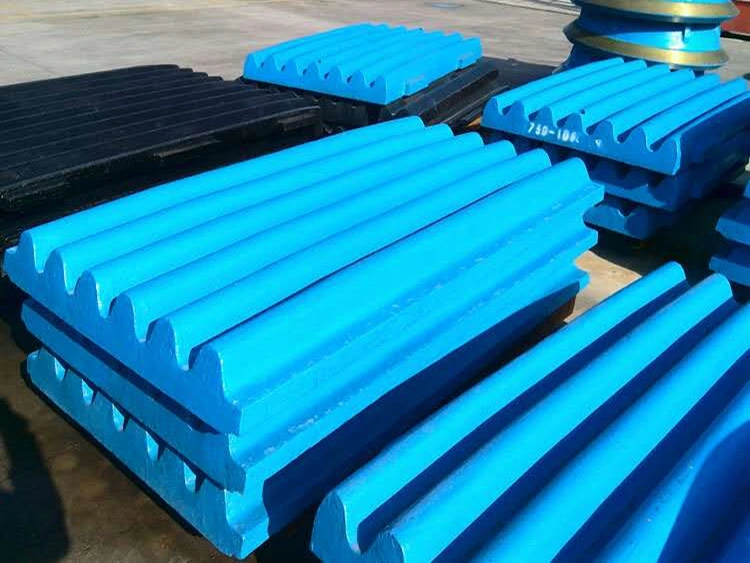

The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed jaw plate and a 1 piece movable jaw plate. In order to rotate and exchange more easily, movable jaw plates also have 2 segments design and 3 segments design. Fixed jaw plate, which installs in the jaw crusher body. Normally, it has two kinds of designs, one-piece design, and two-piece design. Movable jaw plate, which installs in the moving jaws. Normally, it also has two kinds of designs, one-piece design, and two-piece design.

- Common Aliases: Jaw crusher liners, Fixed jaw plate, Movable jaw plate, Swing jaw plates, Manganese jaw liners

- Main Material: Mn14, Mn18, Mn22, Manganese alloy steel, Manganese steel with TIC inserts

- Cast Methods: Lost foam casting, Sand casting, V-method casting

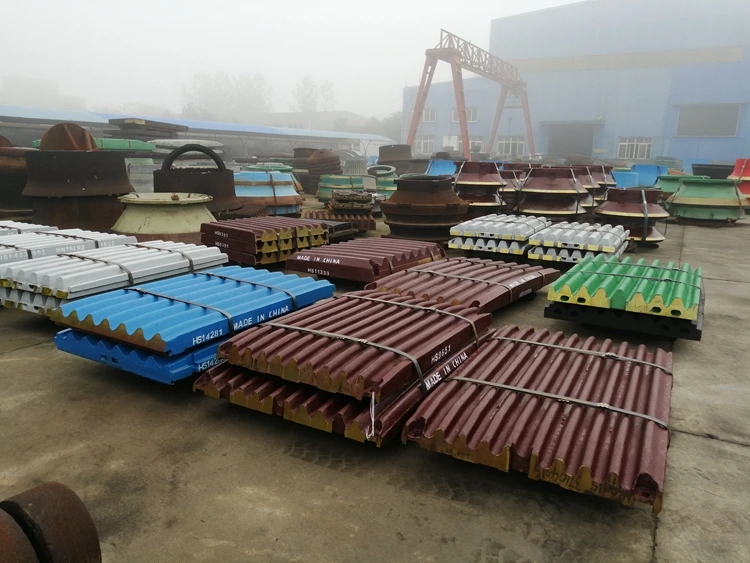

Crusher Jaw Plates By Hunan JY Casting®

When it comes to crusher jaw plates, Hunan JY Casting manufactures high-quality replacement jaw plates for popular brands. No matter which brands crusher jaw plates you want; No matter which material jaw plates you need; No matter which tooth type of jaw plates you inquiry; JY casting is your first choice! In some cases, our manganese jaw plates lifetime 100% match the original wear parts; In more cases, our redesign jaw plates lifetime is 1.5-2 times than the original wear parts.

Hunan JY Casting’s Crusher Jaw Plates Suit:

Crusher Jaw Plates FAQ

Which Material Hunan JY Casting manufactures for crusher jaw plates?

Manganese Jaw Plates

Hunan JY Casting manganese steel jaw plates are made in our own materials that have been developed from the original Hadfield’s manganese steel specification. Our variations can provide unequaled toughness with excellent resistance to abrasion, which improves as the steel work hardens in operation. Available in M14, M18, and special order M21 manganese steel we have a cost-effective solution to your specific requirements.

Modified Manganese Jaw Plates

When crushing some material (such as copper mines stone), the standard manganese jaw plates can not get a long lifetime. So, Hunan JY Casting engineers change the metallographic structure of the product by adjusting the ratio of manganese to carbon and adding some trace elements to obtain a more suitable life. Based on customer feedback, this modified manganese jaw plate’s lifetime can be 1.5 times than the standard material parts when crushing copper mine.

Manganese Steel With TIC Inserts Jaw Plates

When crushing hard stone, the manganese steel jaw plates can not work for a long time. Even the Mn22Cr2 jaw plates also can not get a good result. In order to solve this problem, Hunan JY Casting engineer inlaid the titanium carbide rods on the working surface of the jaw plate. When crushing the stone, the high-hardness titanium carbide rod first touches the stone, thereby improving the hardness and wear resistance of the jaw plate.

When to change crusher jaw plates?

There are two kinds of situations that need to change the jaw crusher liners:

- The jaw crusher liners need to change before they are worn through, in order to avoid damage to the crusher components. Different types of jaw crushers, the situation is different. Such as C105 and C3055, the jaw dies design on the ends is different. The locking wedges on these crushers are located behind the jaw dies rather than at the top of the jaw die. Jaw dies can be allowed to wear until the thickness is 60 to 65 mm thick, or the teeth are worn flat.

- When you have a 10% production loss, compared to peak production, it’s time to change your liners. This means monitoring the amount of stone going through the crusher. In the case of jaw crushers, as the liners wear down, the feed opening at the top of the crusher will constrict, and you’ll lose throughput as the opening decreases and crushing cavity volume is reduced. Failing to do so at that point will cost money in lost production and, if the liner wears too thin, could cause severe damage to internal crusher components.

How to change crusher jaw plates?

Normally, there are 13 steps to change new jaw crusher plates:

- Prepare to work tools:600 live-mouth wrench, wire rope, hand hammer, mast, sledgehammer, electric welding, crane

- Prepare new jaw plate

- Stop the feeding and the operation of the crusher, pay attention to wearing insulated gloves to prevent wet hands and electric shock.

- Remove the screw of the old jaw plate

- Remove the side plate, loosen the side plate screws, and lift the side plates with the overhead crane

- Remove the clamps and slowly remove the stationary plate clamps and place them next to them.

- The welding hoisting ring is welded to the moving plate and the fixed plate respectively. Be sure to solder firmly to prevent bruises during lifting

- Lift the jaw plate and start the crane to lift the moving plate and the fixed plate and transport it to the storage area of waste materials. It should be noted that there is a need for monitoring during the opening of the crane. There can be no people under the crane to avoid bruising, and the wire rope should be strong.

- Lift the new jaw plate, and start the crane to hang the moving plate and the fixed plate separately.

- Install the clamps, place the clamps in place, and tighten the screws.

- Tighten the stationary plate screws and install the side plates.

- Adjust the gap of the discharge port.

- Start the jaw crusher and vibrate the mine for trial operation.

When to rotate the crusher jaw plate?

The ideal situation would be when even wear occurs throughout the jaw plate area, using all the manganese teeth, eliminating the need to execute the “turn”, or change production.

This is impossible, however, because there are areas where we cannot avoid more severe wear than in others, mainly because of the crushing movement geometry, such as in the fixed jaw plate lower tip and the central area of the swing jaw plate, so a turn should be carried out to achieve better performance and use. We recommend a double turn, in other words:

Fixed jaw plate – use until wear of about 50% occurs in the lower area and make the first turn. Make the second turn when wear from 90% to 100% occurs in this new lower area. Conclude using the remaining 50% of the life cycle of this extremity.

Swing jaw plate – the same procedure is applied to the swing jaw plate because although the wear occurs in the central area, it rarely occurs in the exact middle of the jaw plate.

Some notices:

For one-piece jaw plates:

- After a new jaw dies installation, rotate the single-piece jaw dies when 30% of the tooth profile is worn.

- Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn.

For two-piece jaw plates:

- Worn-out jaw dies are removed from the bottom of the crushing chamber.

- Work hardened upper jaw dies are installed at the bottom of the crushing chamber.

Which is the best material for crusher jaw plates?

Standard Manganese Steel

The standard material for jaw plates is manganese steel, which is also called austenitic manganese steel or modified austenitic manganese steel. There are three common grades:

- Mn14Cr2

- Mn18Cr2

- Mn22Cr2

Those Chemical Composition Mechanical as the following table:

|

Mn (%) |

C (%) |

Cr (%) |

P (%) |

S (%) |

Si (%) |

|

|

Mn14Cr2 |

11-14 |

1.15-1.25 |

1.5-2.5 |

≤0.05 |

≤0.04 |

0.3-0.8 |

|

Mn18Cr2 |

17-19 |

1.15-1.3 |

1.5-2.5 |

≤0.05 |

≤0.04 |

0.3-0.8 |

|

Mn22Cr2 |

21-23 |

1.1-1.4 |

1.5-2.5 |

≤0.05 |

≤0.04 |

0.3-0.8 |

The selection for those three kinds of material is as the following:

| Material | Applications | Properties |

| Mn14Cr2 | hardest material, mildly abrasive material | highest impact resistance, low abrasion resistance |

| Mn18Cr2 | harder material, medium abrasive material | higher impact resistance, better abrasion resistance than Mn14 |

| Mn22Cr2 | hard material, most abrasive material | less impact resistance, better abrasion resistance than Mn18 |

Modified Manganese Steel

This modified material is developed by Hunan JY Casting for copper mine customers. When crushing some material (such as copper mines stone), the standard manganese jaw plates can not get a long lifetime. So, Hunan JY Casting engineers change the metallographic structure of the product by adjusting the ratio of manganese to carbon and adding some trace elements to obtain a more suitable life.

Manganese Steel With TIC Inserts

When crushing hard stone, the manganese steel jaw plates can not work for a long time. Even the Mn22Cr2 jaw plates also can not get a good result. In order to solve this problem, the Hunan JY Casting engineer inlaid the titanium carbide rods on the working surface of the jaw plate. When crushing the stone, the high-hardness titanium carbide rod first touches the stone, thereby improving the hardness and wear resistance of the jaw plate. This kind of material lifetime can be 1.5- 2 times than normal manganese steel.

Why Hunan JY Casting’s Jaw Plates

There are many jaw crusher plates manufacturers in the world, why choose Hunan JY Casting as the first choice?

- Various materials can be chosen. No matter standard manganese steel, manganese alloy steel, manganese steel with TIC inserts, or other OEM material, Hunan JY Casting engineers to help you get the right choice.

- Directly price from the foundry. You can get a price directly from our foundry, no third party.

- Quality stable. We have complete control over quality at every step of the process, from the selection of raw materials to final production.

- Better quality. Our premium jaw crusher wear parts are designed to provide extended wear life, lower cost per ton, and optimized capacity and performance.

- Large selection of tooth and curve configurations for optimum performance in any application.

- Titanium Carbide (TiC) material options for incredible wear life