What is TIC Inserts Crusher Jaw Plates?

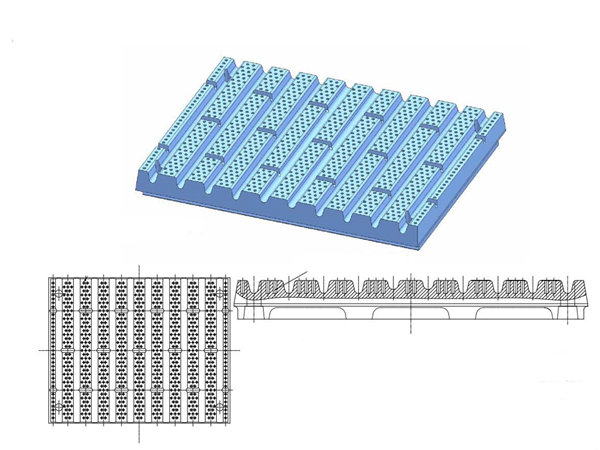

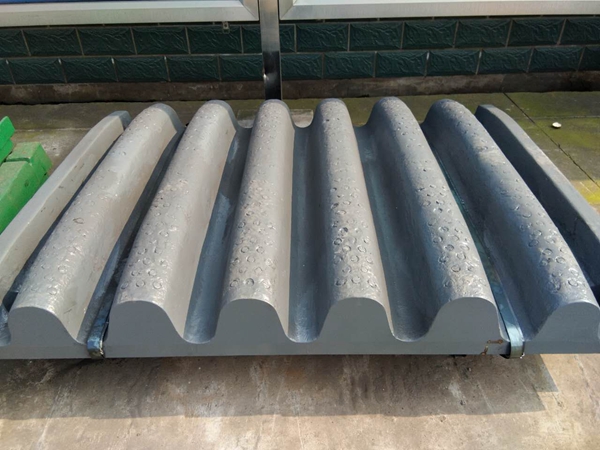

Hunan JY Casting uses titanium carbide rods to insert into crusher jaw plates’ tooth area. With this design, our TIC inserts cone liners have a better working life in crushing hard stone.

Why choose this design?

We have some customers who use jaw crushers to crush very hard stones. Even with the best Mn22 jaw plates, the liners have a short lifespan. Our customer told us his manganese PEW760 jaw plates just work around 165 hours.

After analyzing the customer’s crusher working condition and wear of the old liners, our engineers designed TIC inserts liners for him.

How it prolong span life?

When the stone enters the cone crusher, titanium carbide rods are hit first. Due to the high hardness of titanium carbide rods, titanium carbide rods wear very slowly. On the other hand, the small broken stone touches the gap of two rods. Crushed small stones have low impact, but can also harden areas of high manganese steel matrix. When the rods worn out, the manganese steel matrix had hardened. This is the reason why TIC inserts cone liners span life more than manganese steel cone liners.

Feedback about TIC inserts cone liners

Case Study 1: Philippines customer, PEW760 jaw crusher

Before: Normally, the Mn18Cr2 crusher jaw plates work 160 hours

After Switching to Hunan JY Casting TiC: Our TIC inerts jaw plates span a life of 412 hours. 2.575 times than normal manganese jaw plates!